An Operator's Dilemma

Situation

Derek has been a machine operator for 23 years and has developed a sense of when his machine is not operating optimally. At times Derek notices that the machine makes strange noises, appears to slow down for some parts, or pauses slightly during the machining operation. Derek machines castings that are supplied by three companies and he suspects that differences among the castings have impacted the part's critical dimensions. Derek has talked to his supervisor and other operators about his suspicions, but everyone says the suppliers must be OK because the parts meet specifications.

After a particularly frustrating day, Derek decides to keep a log that records the parts that he measured, the suppliers of the parts and the measured values of the critical dimensions. To simplify the log, he plans to record the measurements from one part each hour. The only problem he has is that he doesn't know how to analyze the data to find out if the supplier's parts are different.

Available data

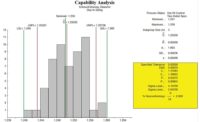

The data that Derek collected for two 12-hour shifts is given in the table "Machined Parts." The two critical dimensions are the heights, Height A and Height B, which are measured from the base of the part. The data values and specifications are coded in thousandths above 0.5 inches. The specification for Height A is 20 + or - 10 and the specification for Height B is 70 + or - 10.

Questions

1. When Derek asked how to analyze the data, he was told to make a process behavior chart. What can Derek learn from a process behavior chart of Height A and Height B?

2. What other method can Derek use to analyze his data?

3. Do the castings from the three suppliers differ?

Answers to January Brain Teaser

Q: How should Stacey analyze these data?

A: The best way for Stacey to see the behavior of the press over a period of time is to put the data on a run chart. If he then analyzes the data using an XmR chart, Stacey will see that the press operates efficiently for two to three days after the preventative maintenance. By day three, the stickiness reappears and escalates over the next several days of production. By the ninth day, the press has reached a point where the average number of times a bun sticks to the machine is 42.5 in a 10 minute period; it appears to level off at this point. See the chart "Number of Stuck Buns at the Press." By this time, the press is scheduled for maintenance.

Q: What can Stacey learn about the overall behavior of the press by analyzing the "stuck" bun problem?

A: If Stacey studies the "stuck" bun problem several times and sees the same pattern of behavior, he can begin to predict the behavior of the press with respect to the sticking problem.

Q: How can Stacey use these data to determine a better maintenance schedule for the press and still meet production targets?

A: After Stacey has enough evidence of the pattern of behavior with respect to the stickiness of the press, he can evaluate the cost of paying an employee to separate the stuck buns versus the cost of additional lubricating maintenance for the machine. Any additional maintenance procedures need to be done quickly so as to minimize the impact on production. If it is advantageous to schedule lubrication maintenance every two to three days, he can modify the maintenance procedure.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!