Smart Cameras' Structure and Uses

Almost all machine vision tasks can be solved with smart cameras. Source: Vision Components

Until recently, PC systems were predominantly used for machine vision applications, but now intelligent cameras are used in increasing numbers. Smart cameras differ from conventional industrial cameras without intelligence-they include all substantial functions beyond the CCD sensor, such as frame grabber, image memory, a fast digital signal processor (DSP), as well as all necessary interfaces for communication with the process and the external world. This article will show that even complex tasks can be solved using smart cameras.

The fundamental idea behind the development of the intelligent camera was that with appropriate miniaturization it should be possible to accommodate in the same housing, not only the electronics controlling image sensor, but also a completely embedded computer together with frame grabber and process interfaces.

Smart cameras can be used for inspection tasks requiring economical installation in a small space. Source: Vision Components

Smart Camera Structure

For image sensors, high-quality CCD sensors are used in most cases. Some manufacturers use inexpensive CMOS sensors because of cost, which prove to be insufficient in many applications. For standard resolution, the VGA 640 x 480 pixel resolution has become generally accepted. Sensors are available up to two mega-pixels (1600 x 1200 pixels) for applications requiring higher resolution.The short-time electronic shutter is a special feature of CCD sensors. With a CCD it is possible to freeze snapshots with exposure times down to few microseconds. An application example of the electronic shutter is measuring small marks at speeds up to 10 meters per second in the graphic arts industry.

The sensor data are digitized and transferred through direct memory access (DMA) into the main memory (SDRAM). A full eight-bit digitization is usually sufficient.

A Texas Instruments TMS320C64xx digital signal processor (DSP) is at disposal to process the image data. With one gigahertz clock rate the processor yields 8000 million instructions per second (MIPS) executing eight operations at the same time. Such a massive computational power is necessary because enormous data sets must be processed with typical cycle times of 0.1 to 1 second per part. Moreover, the development of high-performance and computing-hungry software algorithms will continue for a long time. Consequently the fastest available system is just good enough for image processing.

Even the fastest processor is of no use if it is not able to communicate its computational results to the external world. For example, four inputs and four 24 volt outputs connect to photoelectric sensors, PLC signals or pneumatic valves. Larger data sets can be transferred over the TCP/IP- enabled Ethernet interface. This allows for feasible picture transmission to a control computer for easy operator interaction or for record-keeping purposes. The Ethernet also can serve for extending the input/output (I/O) capabilities. By this means, the intelligent camera can completely take over the task of a programmable logic controller (PLC). Configuring smart cameras over HTTP browsers, remote maintenance and retrieving statistics over ftp are other options enabled by this communication standard.

A smart camera can grab and process images autonomously and does not need a monitor connection to display images. However, such a connection is practical at installation and trouble-shooting. For instance, the image of the last defective part can be displayed during production to provide valuable indications of weak points in the production. Another option is to operate the software through a menu displayed on the monitor with an optional keypad.

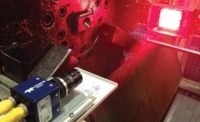

Even complex tasks can be solved using smart cameras. Source: Vision Components

Smart Camera Uses

Almost all machine vision tasks can be solved with smart cameras. The small size often is an advantage for the customer and a control cabinet can be eliminated. Intelligent cameras do not include wearing parts such as hard disks or ventilators that require maintenance. On the other hand, there are some applications where a PC is already available. In this case, operators will often choose a solution with conventional cameras. In such a case, one should weigh whether the PC could be relieved by using smart cameras. If several cameras are connected, a substantial increase in the machine cycle rate can be reached on occasion.The following application from the graphic arts industry is an example of the diverse possibilities of use. For multicolor printing the individual color printing plates must be positioned precisely relative to each other. Otherwise the printed image will be blurry, shady or become completely unreadable. For each color a registration mark is printed to control the correct adjustment. Different mark shapes are used, such as small crosses or points. The marks can be printed on the edge outside of the actual print area. In some small applications, nearly invisible micromarks are used that can be accommodated within the printed page, saving valuable paper.

The task of the smart camera is to precisely measure the distances of the color marks to each other. Typical accuracies of 1/10 of a pixel translates down to one micrometer depending on the actual scale. In case of any deviations from the nominal target position, the position of the printing plates is readjusted accordingly.

The high Web speed reaching up to 10 meters per second creates a special challenge for this application. Even at this speed, completely sharp pictures that can be measured with fractions of a pixel must be captured. For this purpose, the special features of the ultra-short-time electronic shutter come in handy. Shutter times as short as five microseconds make it possible to freeze even extremely fast moving incidents. An incremental encoder connected to the transport roll triggers the image capture. Each time a predefined number of impulses is detected, a picture is captured. As a result, the marks always appear at the same position in the picture. Jitter-free image capture is critical. It means that the random time delay is absolutely zero between the reception of the trigger signal and the actual image capture delay. Otherwise, at the high Web speed, the marks would not be in the correct position of the image field.

The image processing algorithms for this application are quite simple to understand. First the marks have to be found in the image field. The position deviation is very small from one picture to the next, consequently one can limit the size of the search window. Although the print marks are colored, they can be found with a black-and-white camera. In order to improve the recognition reliability of the yellow register marks, an additional color filter can be employed in front of the sensor, which increases the contrast for this color. Binary search techniques present the simplest method, providing the the center of gravity’s position for each mark found in the picture. Another common and reliable search method is the standardized grey scale correlation.

Search methods are able to determine the position of the marks with approximately one-pixel accuracy. In order to determine the position with even higher accuracy, special subpixel accuracy measurement techniques are applied. With good contrast they can easily deliver factor ten accuracy. Still higher accuracies are possible depending on the boundary conditions of the individual case. Despite the high Web speed, the repeat rates for printing presses lie only in the middle range. Usually a 30 to 60 framers per second (fps) smart camera is completely sufficient for this task. In fact, the technology could accommodate even higher speed up to 250 fps.

Additional Applications

Smart cameras can be used for inspection tasks requiring economical installation in a small space. The typical installation is an OEM product in machine-building applications to facilitate integrated quality control inside of a machine.Common application fields include: quality and completeness control; industrial production processes; measurement technology; filling control, packaging, blister; 1-D and 2-D bar code reading, optical character recognition; verification of date codes and batch numbers; and 3-D measurement with laser triangulation.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!