Quality 101

3-D Measurement: The Basics

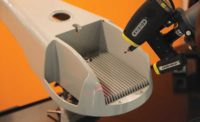

While CMMs are still industry staples, the versatility, quickness and ease-of-use of a 3-D scanner makes it most manufacturers’ measurement tool of choice.

There are good reasons why traditional contact measurement machines (CMMs) have been staples in manufacturing’s quality control environments for decades. These machines—which collect data points wherever a probe meets a surface—are known for generating high-accuracy measurements and automation abilities. But since they are expensive, stationary tools, they can leave something to be desired.

For many manufacturers—especially those in the automotive; aerospace; power generation; oil and gas; medical; architecture and art industries—optical 3-D measuring devices can fill this need. This technology is not only increasingly affordable, portable and compatible with most standard inspection procedures; it is known for offering increased shop-floor accuracy and higher measurement speed than traditional CMMs.

What Makes 3-D Measurement Necessary?

Modern 3-D measurement is only necessary in terms of what your competition is doing, says Steven E. Kersen, vice president of Sales and Marketing at NVision Inc.

“There were a lot cars and airplanes made without 3-D scanning; however, the ability to now make parts much faster is driving people to use 3-D scanning more often,” he explains.

When it comes to validating that the manufacturing process has delivered the required specifications, however, there is no better method than 3-D. “Since parts cannot be manufactured to CAD nominal because of process variables, 3-D measurement ensures the part is manufactured within its specified tolerances,” explains Kersen. “The better the measurement, the better understanding you have to improve your manufacturing processes.”

CMM or 3-D?

Some manufacturers are accepting 3-D measurement more quickly than others.

“Many [CMM] systems have been installed for over a decade,” says Rick White, director of business development for Capture 3D. “These technologies are very entrenched in many industries and the CMM measurement technique is part of the process for their manufacturing acceptance criteria.”

CMMs are also preferable for measuring machined parts with prismatic shapes, such as holes, cylinders, planes and spheres. A traditional CMM will still measure these features much more accurately than a non-contact scanner can.

But that doesn’t mean that 3-D measurement hasn’t sufficiently caught on.

“Non-contact 3-D scanning technology and software has evolved the metrology marketplace,” White explains. “Engineers are able to obtain full part geometry accurately in rapid time with almost instantaneous inspection reports. Not only are we able to quickly determine what is occurring at specific points, but the surrounding areas thus giving more information to make the correct corrective action.”

In addition, those who previously used calipers or hand tools to measure to shapes with curvature have found drastic improvement through switching to scanning. “People do use traditional large CMMs to sometimes reverse engineer; however they must be programmed and it can take several days if not weeks, whereas 3-D laser scanning doesn’t need programming,” Kersen explains.

3-D measurement software offers the added benefit of making process-specific inspection user-friendly, because it can be operated without specialized programming skills.

“This enables companies to speed up design, manufacturing and production processes while improving quality for a quicker time-to-market in order to stay competitive,” says Kerson.

According to White, 3-D scanning has become so prominent, it’s dominating the measurement market.

“Contact based measurement solutions are finding it more difficult each year to compete and maintain market share,” he says. “Many process-improvement oriented companies are implementing structured white/blue light non-contact measurement solutions to improve both their throughput and product quality. Aside from measuring their parts more quickly, the manufacturer learns more about the parts they are making, helping them to make better parts, reduce scrap and improve processes.”

Is 3-D Measurement Changing? Yes, Yes It Is

“There has been amazing improvement in both time to acquire data as well as the accuracy,” says Kersen. “In the mid 90s, 3-D scanning was just taking shape. The collection rates were 9,000 points-per-second. Now systems commonly acquire 60,000 points-per-second and even more.”

The areas of coverage have skyrocketed in size, too. Laser systems started out covering 1.5-inch stripe widths, and now they can encompass stripe widths up to 10 inches.

“The other vast improvement is the speed of computers to handle high density data and the software to process it,” Kersen continues. “ Nvision’s largest customers at the beginning were seating clients such as Lear, Johnson Controls, Aurelia. When scanning a seat, the engineer would have to wait a couple of minutes for the screen to refresh when changing view angles. To process data to a usable CAD or inspection file could take hours. At present it is usually done in a few minutes.”

Kersen says the accuracy of 3-D systems will continue to increase, but much more incrementally. A portable system could tend be less accurate than a non portable system, such as a traditional CMM.

“The speed of data acquisition is also still increasing, but we are reaching a point that millions of points-per-minute is more than enough to define a part,” says Kersen.

The Cost Factor

As 3-D measurement becomes a more popular tool of choice, it has also become cheaper: Many low-end systems can be found for less than $20,000.

“This will allow other industries using hand gages to start to think about scanning,” Kersen notes. “It is important to note that accuracy is directly related to price in that lower price equals lower accuracy; higher price equals higher accuracy.”

White says that the process is simply becoming more democratized. “We believe that we will continue to see faster, more accurate systems designed for specific applications,” he says. “Non-contact 3-D automated solutions have become more prevalent to ensure process repeatability and increase throughput. As these technologies penetrate the industry, the prices will naturally come down based upon the volume of the market.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!