Corporate GD&T Implementation

When properly implemented, GD&T makes a big contribution to corporate profitability

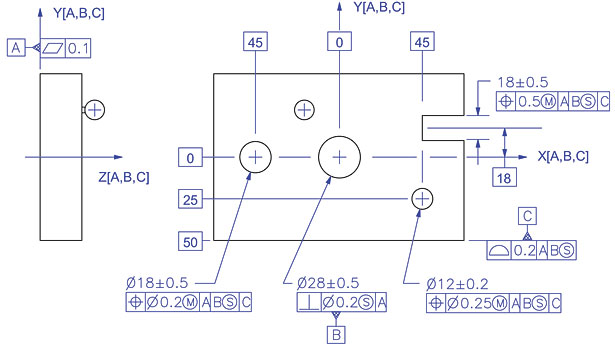

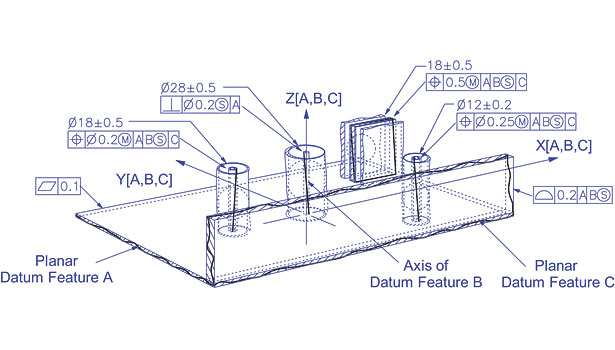

What is GD&T? GD&T, namely “Geometric Dimensioning & Tolerancing,” is a symbolic language with which to 1) research, 2) refine and 3) ultimately “encode” the functions of each feature of a machine part by specifying permissible limits of imperfection which guarantee assembly and operation prior to drawing release.

CAD (Computer Aided Design), and GAD (GD&T Aided Design) are the two equally important halves of the science of machine part geometry specification. CAD provides the means to generate, manipulate and communicate the nominal geometryof machine parts. GD&T, on the other hand, serves to research, refine, “encode” and guarantee the functions of machine part features. CAD without GAD is very “BAD,” because it represents just half the story and fails to guide downstream processes, whereas CAD with BAD GAD, the most common kind, is even worse because it misleads. Without GD&T, and of course syntactically correct and function based GD&T, meaningful tolerance stack-up analysis is impossible, manufacturing depends almost entirely on tribal understandings, and all coordinate metrology is pure invention on the part of the inspector. Thus the lack of any GD&T, and even worse of reliable GD&T, is demonstrably responsible for bumpy new product ramp up cycles, unnecessarily costly manufacturing processes, and questionable inspection results. In short, GD&T is a highly sophisticated “encodable” and “decodable” symbolic language for managing the risks involved in machine part design, manufacturing, inspection and assembly, and getting it right the first time.

GD&T’s Corporate Contributions

Properly implemented, GD&T makes big contributions to corporate profitability. It does so by enabling design engineers to research and refine the operational and assembly functions of parts prior to drawing release, instead of through costly trial and error on the assembly floor. It also does so by “encoding” requirements so clearly as to permit completely unambiguous “decoding” for reliable manufacturing and inspection process management from the get-go. Nowhere is GD&T more important than in the newly disintegrated world of global manufacturing, where its symbolic language makes the user independent of differing tribal understandings, and “allows us to say so precisely what we do, that others can do precisely what we say.”

In spite of this, GD&T is widely neglected and even feared, and frequently raises supplier pricing instead of reducing it. Reasons include:

Inadequate understanding of the code.

Fear that the GD&T found on most drawings is not “code” but mere “decoration” and will cause problems due to differing “interpretations.”

The assumption that GD&T imposes inspection requirements, which it does not. GD&T merely imposes delivery requirements!

Corporate Implementation Strategies

Corporate success with GD&T is critically dependent on top management support. Top management must be aware of the financial benefits of GD&T, must encourage its use and must encourage competence in its use. In the long run, successful implementation depends substantially on building and maintaining an accomplished and empowered “GD&T Advisor” team to do internal training, to provide real time support for engineering, manufacturing and inspection, as well as for dealing with suppliers.

3-D Model Based GD&T

When invented in 1940, GD&T was entirely drawing based and unsupported by computer based tools—one could impose a cylindricity requirement on a planar surface and get away with it. With the advent of CAD, GD&T began to be applied in the computer environment, but mainly in the 2-D drawing mode, with no model based intelligence. In the meantime, model based definition (MBD) has finally come into being, in which syntactically correct, function based GD&T “code” can be generated in a 3-D intelligent environment in which it is clear that an attempt to control the cylindricity of a planar surface makes no sense. Once available, syntactically correct, function based GD&T code can be uniquely “decoded”—not “interpreted”—for automatic assessment by TSUPA (Tolerance Stack-UPP Analysis) software, and automatic conversion into coordinate metrology based inspection programs. Thus it is with the advent of MBD that we can finally “encode” and “decode” GD&T intelligently with rule and best practice based software.

The opportunity is finally at hand to realize the promises of GD&T instead of suffering at its hands. Instead of being “Grim, Depressing & Troublesome,” GD&T will finally be recognized as “Grand, Delightful & Tantalizing”—but only if management pushes, albeit firmly but gently, for its implementation and controlled management.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!