Getting to the Root Cause

Aiming performance improvement measures at root causes is more effective than merely treating the symptoms of a problem.

Problem solving is finding the root cause of a problem and preventing it from ever happening again. Problem solving is not putting a Band-Aid on the problem. Create a work instruction to use when you have to perform a root cause analysis. If you have an instruction, all of the elements will be completed the same way each time.

Root Cause Analysis involves:

- Defining the problem in descriptive or quantifiable terms

- Determining the root cause condition(s)

- Verifying the Root Cause

Actions taken when using the Corrective Action Process:

Containment

Protect the customer, product or process

Corrective Action

Eliminate the designated Root Cause(s)

Preventative Action

Implementation of actions to prevent recurrence of the root, contributing or direct cause conditions

Root Cause Analysis is the process used to reach the primary cause or causes of a problem. Root cause is the core reason or reasons that the problem exists.

Aiming performance improvement measures at root causes is more effective than merely treating the symptoms of a problem.

Root Cause Analysis (RCA) is effectively performed on the issue. RCA is performed systematically, with conclusions and causes backed up by documented evidence.

There is usually more than one potential root cause for any given problem.

To be effective the analysis must establish all known causal relation-ships between the root cause(s) and the defined problem.

Root cause analysis transforms an old culture that reacts to problems to a new culture that solves problems before they escalate, creating a variability reduction and risk avoidance mindset.

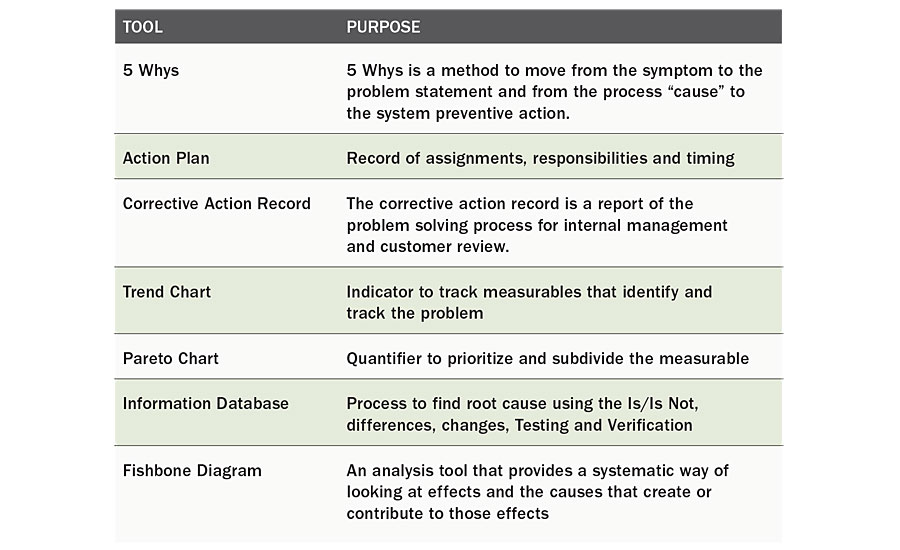

The basic elements of RCA may include the following. However, this list is just a starting point.

Materials

Defective raw material

Wrong type of material for the job

Lack of raw material

Machine / Equipment

Incorrect tool selection

Poor maintenance or design

Poor equipment or tool placement

Defective equipment or tool

Environment

Orderly workplace

Job design or layout of work

Surfaces poorly maintained

Physical demands of the task

Forces of nature

Management

None or poor management involvement

Not paying attention to the task

Task hazards not guarded properly

Other (horseplay, inattention....)

Stress demands

Lack of Process

Methods

Practices are not the same as written procedures

Poor communication

Management system

Training or education lacking

Poor employee involvement

Poor recognition of hazard

Previously identified hazards were not eliminated

Put a cross-functional team together before you start your problem solving steps.

Problem Solving Steps

Assemble a cross function team to work on the problem.

Problem Statement

Describe the problem in descriptive or quantitative terms. Establish the operational definition or problem statement and observe the process. Gather information on previous defects and determine where in the process the defect is happening.

Containment needs to be performed to protect the customer from receiving any bad product.

Describe in as much detail the symptoms of the rejection.

Find the Root Cause and Verification

Prepare a Cause and Effect Diagram

Review and update the Process Flow Diagram (if necessary)

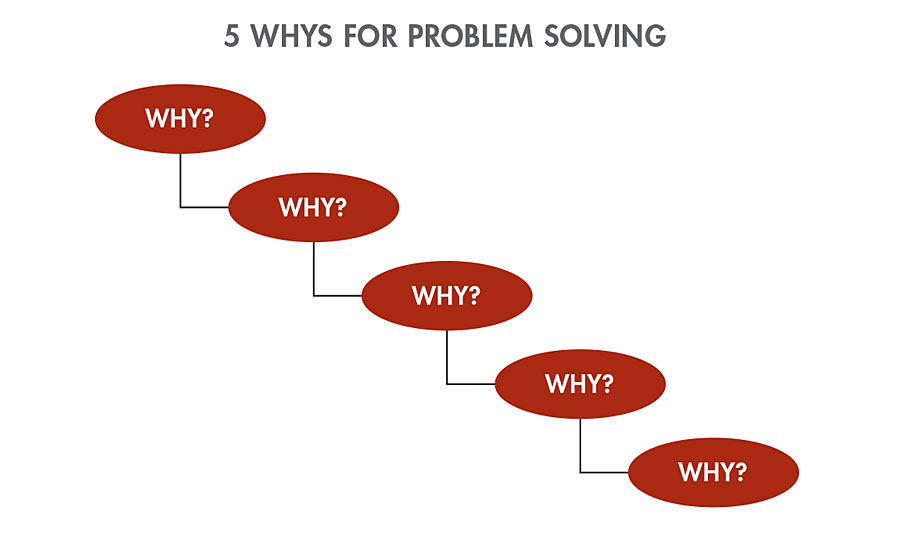

Repeated 5 Whys

Identify the difference in good versus bad

Notes: The key to finding the root cause is asking the question: “What Changed?”

In listing the changes, dating the change is critical. Think about how the date of a change can be helpful.

Develop Theories

Record ideas of what could have happened using the brainstorming method

Test and eliminate potential root causes and verify the selected root causes.

ROOT CAUSE QUESTIONS

Is there a relationship between the problem and the process?

Is this a unique situation or is it the root cause? Is it similar to previous rejections?

Why have we not we experienced the problem before?

What changed?

- Do you have new suppliers?

- Change in tooling or new tools?

- New operators?

- Did the process change?

- Did the measurement system change?

- Are the raw materials used the same?

- Are we using customer supplied product?

- Do other similar operations have the same problem?

Barriers to Root Cause Analysis

Not using a system

Leads to incorrect root causes

Unverified corrective actions

Lack in customer satisfaction

Using the incorrect tool

Not following the corrective action format

Over-reliance on experience

Keep the guesswork out of the process

Keep an open mind

Resistance to change

We have always done it this way

7. Select the Permanent Corrective Action

Choose and verify the best action

Validate with before and after data

Permanent Corrective Action Questions

What Permanent Corrective Actions did you consider?

What indicators have we used to verify the PCA?

Are the indicators related to the root cause(s) of the problem?

What is the frequency and interval that we need to measure this problem?

Hourly

Daily

Weekly

Monthly

What methods will you use to verify the effectiveness, both in the short term and to predict the long-term results?

Is the PCA acceptable to the customer?

Will this PCA create other problems?

Implement Permanent Corrective Action

Construct an action plan and plan the prevention and protection actions. Validate (PCA) with the original problem indicator. Update the FMEA and all of the other related documents.

Implementation Questions

Have you defined the action plan?

Have you assigned the responsibilities?

Have you established the timing?

Have you obtained the required support?

What indicators are you planning to use to verify the outcome of the actions, both short term and long term?

Have you communicated the action plan to all parties?

What controls do you plan to put in place to assure the permanent fix is working?

Prevent Recurring System Problems Questions

Can we use our improvement on another existing process?

What allowed this problem to occur?

Was it a failed procedure?

Was it a system breakdown or failure?

Did we use our best practices?

What practices do we need to standardize?

Have you written the plans to coordinate the actions?

Who is responsible?

What are the action items to be completed?

Assign a date for the action items to be completed.

How will we communicate the new practices to all of employees affected by the change?

Are document updates necessary?

Flow Chart

FMEA

Control Plan

Work Instructions

Digital Photos

Samples Good and Bad

Routing/Traveler

PPAP

8. Congratulate the Team

Determine the appropriate recognition, and celebrate successful completion.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!