Quality 101

Why Perform Friction Tests

Combining versatile friction tests and surface texture measurements

Figure 1. Interchangeable test modules for the UMT TriboLab system from Bruker. Source: Bruker

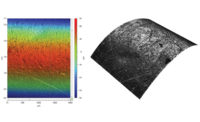

Figure 2. Surface texture height map of a piston sample measured by a 3D optical microscope.Source: Bruker

Figure 3. The Abbott-Firestone curve and volume parameters calculated with imaging and metrology software from the measured 3D surface texture data. Source: Bruker

When material surfaces are in mechanical contact and slide against each other, complex microscopic interactions occur between the surfaces that lead to friction and wear. Factors that affect friction behaviors include a component or part’s materials, the topographical characteristics of the surfaces, and the surrounding conditions, such as temperature, atmosphere, and chemical and biological environment. Friction is a popular field of study across many different industries, ranging from aerospace and automotive systems to medical implants and devices. Typical areas of friction studies include:

- Surface engineering of materials

- Friction and fuel efficiency

- Friction and wear of materials

- Friction induced corrosion

- (tribocorrosion)

- Biotribology

In the United States, the direct and consequential economic loss due to friction and wear is estimated to be approximately 1% to 2% of the annual GDP. For example, in the automotive industry, friction between moving components can result in energy loss and reduced fuel efficiency. Roughly 10% of energy consumption in an automobile is caused by friction. The reduction of friction in engineered materials and surfaces of automotive components has been reported to improve fuel efficiency by 3% to 5%. Friction is also widely studied in the medical implants and devices industry, as the friction and wear of implant materials and devices in a human body can cause inflammation or even toxicity through the generation of wear debris. For instance, the US Food and Drug Administration (FDA) issued a special safety letter on Nov. 23, 2015, cautioning manufacturers on the issues with friction-reducing coatings on medical wires after examining 11 product recalls and 500 adverse event reports that included nine deaths. The FDA said in some cases slippery coatings flaked off due to friction and clogged the flow of blood.

WHAT KIND OF TESTER SHOULD BE USED

Because friction is a system property, not an inherent physical property of a material, a common question for many engineers is how to properly measure friction in the lab that adequately simulates the real-world environment and conditions. There are a myriad of factors that need to be accounted in setting up realistic and truly meaningful friction tests, such as high temperatures, humidity, and liquid immersion, to name just a few. Being able to replicate and simulate the application conditions is critical to generating friction testing data that can be used to improve the quality of manufactured products.

Most commercially available instruments for friction tests are single-function testers, which makes it difficult, if not impossible, to use the same testing equipment for different tests. Even on a single part, there might be several different tests needed to adequately understand performance and durability. And if you are a manufacturer of more than one product, each of the products would need individualized tests. The good news is that there have recently been advances in the testing instrumentation field and there are now some advanced friction testing systems available that offer a range of modules to enable users to run a wide variety of different friction tests on the same testing platform. The better designed systems allow one to change from rotary to reciprocating motion, from sub-newton to kilo-newton force measurements, or from room temperature up to 1000°C for environmental testing. The biggest advantage of these kinds of systems is that they allow the user to more easily tailor tests to specific requirements, which is really the heart of effective testing.

WHY SURFACE MEASUREMENTS ARE ALSO NECESSARY

However, testing the friction behavior is only part of what a manufacturer usually needs for a part or component. It is equally important to characterize the surfaces of the materials. Using appropriate surface metrology tools to measure and analyze the engineered surfaces sheds light on the fundamental reasons for the specific friction behaviors, and enables engineers to make more informed decisions faster.

Traditionally, a simple optical microscope or a scanning electron microscope is used to image material surfaces. Although such imaging instruments are good for providing general surface morphology information, they cannot provide the quantitative measurement of critical surface texture parameters, such as those defined in the ISO 25178 standard. A 3D optical microscope is an ideal tool to quantify the functional surface texture parameters, which have very important values for all mechanical parts that are in contact with another part. Three-dimensional optical microscopy based on white light interferometry (WLI) is one of the most accurate, repeatable, and fastest methods for precision surface measurements from nanometer to millimeter scales.

Functional surface texture parameters are related to the distribution of heights and are used to characterize functional behaviors of the surface, such as wear, lubrication, and contact. Using advanced data analysis algorithms, functional surface texture parameters can be calculated and reported from the highly accurate data collected by a 3D optical microscope or optical profiler.

Figure 2 shows an example of the surface texture height map of a piston sample measured by a WLI-based 3D optical microscope, which has the benefit of revealing surface texture in all three dimensions. To quantify the surface texture parameters, engineers typically use analysis techniques such as the Abbott-Firestone curve shown in Figure 3 to decipher the measurement data collected by the 3D optical microscope.

Surface texture parameters defined in ISO 25178, ASME B46.1 and other standards can be easily calculated and reported with modern surface metrology software that is usually included in the 3D optical profiler solutions on the market. For example, the volume parameters summarized in Figure 3 (Vmp or peak material volume; Vmc or core material volume; Vvc or core void volume; and Vvv or valley void volume) help to clearly define the surface’s friction characteristics and lubricant-carrying ability.

SUMMARY

When designing and running friction tests, it is important to replicate and simulate the application conditions in order to generate relevant friction test data. Choosing a friction testing platform that can be quickly adapted for different test conditions and environments has the benefits of providing both flexibility and cost savings to the users. Because friction is directly related to the nature of the materials surfaces, combining friction tests and surface texture measurements is an efficient practice in both R&D and manufacturing. Implementing this approach in product quality control enables manufacturers to reduce part wear and extend system life, improve efficiency or even improve the safety of manufactured products.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!