NDT Personnel Certification and Training: It’s Time to Do It Right

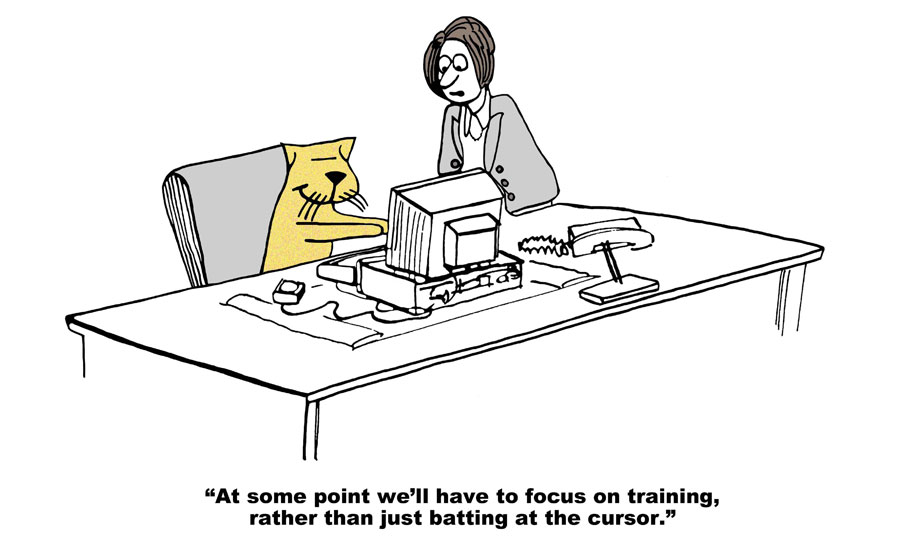

There are still far too many organizations involved with NDT not following the recommended practice or standards.

For decades in the United States, NDT personnel certification has been in a state of chaos. Since 1968, the basic certification program SNT-TC-1A, a “recommended practice” has been adopted and followed by many organizations. Other programs followed such as MIL-STD 410, MIL-STD 271, and NAV SHIPS 250-1500 (all three have gone through name changes). Today there are many more certification programs and several more are being developed. Ideally, there should be one comprehensive national system, but that seems unrealistic at this time. Blatant abuses such as falsifications, improper documentation, and failure to follow established standards and procedures continue to plague the growing NDT industry. Over the years, there has been a tendency to ignore the original intent of SNT-TC-1A, the need to assure that NDT personnel are qualified which is a prerequisite to certification. There are many who believe that SNT-TC-1A is the best approach for the U.S. provided the original intent is achieved.

A Bit of History

The 1945 spring issue of Industrial Radiography, the forerunner to today’s Materials Evaluation, contained an article by Eugene Morze. In his article, “Qualification of an Industrial Radiographer,” he proposed a standard for the qualification of radiographers by examination, leading to certification.

Seventeen years later in 1962, a task group was established to:

- Develop a document that defines in simple terms the recommended levels and qualification requirements for NDT personnel.

- Prepare an examination or test system whereby applicants could demonstrate their qualifications.

- Recommend arrangements for the administration of NDT personnel certification.

The document mentioned in #1 above was prepared by the task group and resulted in much discussion. The document was designated as SNT (Society for Nondestructive Testing) - TC (for Technical Council who developed it) - 1 (a unique identifier) - and (T) for tentative. It was published in the May-June 1963 issue of “Nondestructive Testing.” The designation was changed to SNT-TC-1A and published in 1966 covering five methods: radiography, magnetic particle, ultrasonics, liquid penetrant and eddy current. It also permitted other methods, not specified, to be used. The program that started as an attempt to “register” radiographers became a “recommended practice” for those five methods.

A recommended practice is a set of guidelines to assist the employer in developing uniform procedures for the qualification and certification of NDT personnel to satisfy the employer’s specific requirements. It was never intended to be used as a specification or a requirement. It’s the employer’s responsibility to use it as a guideline to develop their own procedure or “written practice” which then becomes the requirement for the qualification and certification for that company’s personnel.

Training vs. Certification

There is widespread misunderstanding and abuse regarding NDT training, which is only one aspect of qualification. SNT-TC-1A correctly defines qualification as “demonstrated skill, demonstrated knowledge, documented training, and documented experience required for personnel to properly perform the duties of a specific job.” Training is defined as “an organized program developed to impart the knowledge and skills necessary for qualification.” It should be clear that training alone does not satisfy the requirements for certification. Once training is completed by a reputable training organization and documented, the experience as recommended in SNT-TC-1A must also be completed and documented. Doesn’t it sound simple enough? Why then is there such widespread misunderstanding? Here are a just few examples:

1. An NDT course advertised to be 40 hours by a well-known training school administered general, specific, and practical examinations on the last full day of the course. Grades for each of these examinations were provided to the employer of the students who then used them as the certification grades. This is totally inconsistent with the process of proper certification. Training should be for the purpose of imparting the knowledge and skills to the students and should cover the defined body of knowledge. The course should also include sufficient examinations to ensure that the necessary information as stated in SNT-TC-1A is fully comprehended. Training should be done for the benefit of learning and should not be used solely to certify individuals. It is part of the qualification process that leads to certification.

2. There have also been cases where the end of course examination grade has been used for the certification general examination grade. This is inappropriate. The certification process should be totally independent from the training.

3. Another widespread abuse involves radiography. As required by the Nuclear Regulatory Commission and company radiation manuals, radiographers using radioactive sources must take—and pass—a 40 hour course covering the regulations regarding radiation and the safe handling and operation of radiographic devices. It is a common practice to have radiographers who satisfactorily complete their radiation safety training course to automatically be given an RT Level I certification. The body of knowledge, ANSI/ASNT CP-105, contains many subjects above and beyond radiation safety. The most appropriate way to achieve Level I certification is to satisfactorily complete the radiation safety training as defined in the body of knowledge in addition to the other Level I RT course subjects.

4. Then there’s the issue of misleading advertising. One recent example advertises ultrasonic thickness and penetrant testing courses as one that “discusses” the principles, advantages and limitations as well as practical training on “real world” specimens. It further states “Level II certification upon completion of the course.”

5. Yet another recognized training organization states that their courses “conclude with a comprehensive final examination covering all preceding material. This final can be used by an employer as a “General Test” for qualification purposes.” Again, sending out confusing signals suggesting that end of course training examinations can be used in the certification process.

6. Another school advertises that they offer “certification courses” in VT/Optical, PT, MT, RT, RT Interpretation, UT Thickness, UT, and ET!

What Does SNT-TC-1A Say?

The 2016 edition of SNT-TC-1A clearly states that “all qualification examination questions should be approved by the NDT Level III responsible for the applicable method.” How do these schools accomplish this? It further states that “an NDT Level III should be responsible for the administration and grading of examinations specified in Section 8.3 through 8.8 for NDT Level I, II, or other Level III personnel.” If an instructor administers and grades any examination that will be used in the certification process, they must be delegated by the companies Level III and be recorded. In addition, that designee should have documented, appropriate instruction by the NDT Level III in the proper administration and grading of qualification examinations prior to conducting and grading independent qualification examinations for NDT personnel. Additionally, the practical exam should be administered by a person certified in the applicable NDT method as NDT Level II or III.

Certification Issues

There are still far too many organizations involved with NDT not following the recommended practice or standards. Many training courses do not provide the number of contact hours stipulated in the certification schemes. Training certificates are still being falsified, experience times are shortcut or not validated, and there are cases where the administration of certification examinations is not done under secure conditions. In another case, practical examination specimens which are supposed to be kept under secure storage conditions were found in a van with the examination candidates. And the abuses continue and are widespread.

Areas of abuse, noncompliance or concern include:

1. Individuals offering outside agency services whose qualifications to provide these services have not been reviewed by the employer engaging the company or individual.

2. The periodic technical performance evaluations as defined in the employer’s written practice are not being conducted. NDT Level I and II personnel are supposed to be reevaluated by the NDT Level III by administering a practical examination.

3. Training courses and training records are not being validated to assure the necessary subjects are being presented and that the proper number of hours have been satisfactorily completed and documented. (see reference #1)

4. Taking the initiative to evaluate the training organization in advance of the training to provide assurance that the courses cover the body of knowledge and that qualified instructors are being used. Also, that the equipment to be used for the practical training is available in adequate quantities and in working condition.

5. Interrupted service should be addressed in the employer’s written practice and should include rules covering the types and duration of the interrupted service that will require reexamination and recertification. In too many cases, this is not included in the written practice or not following in the event of non-performance of a specific NDT method for the time specified.

6. One widespread practice has to do with the questions used in the general examinations used in the certification process. SNT-TC-1A stipulates that sample general question booklets are available from ASNT. These questions are intended as examples only and should not be used verbatim for qualification examinations but in many cases they are.

Solutions

As mentioned earlier, there are far too many certification schemes currently in use in the United States. (See Compendium.) One solution is to merge those schemes that are similar and delete those that are outdated or are no longer being applied.

Another solution would be to move forward with the adoption with an internationally recognized certification scheme such as ISO 9712. ASNT had an opportunity to do this when the first edition was published in 1992. It was seen by many whom were long-time advocates of central certification as a major improvement, which could ultimately provide uniformity, and international mutual recognition of NDT personnel who carry certifications to this program. After much review and discussions by various committees, the ASNT certification board, as it was known at that time, was directed by the ASNT board of directors to develop a plan for compliance with ISO 9712 for the centralized certification of NDT personnel. The plan to comply was approved by the board in November 1993, and several days later, the same board changed their vote from “comply” to “align.” This effectively killed the attempt to come into ISO 9712 compliance. Alignment just wouldn’t work for the applicable codes and standards industries depended on.

In 2007, ANSI/ASNT CP-106-2007 was adopted. It was based on modifications to ISO 9712. It is now 10 years later, and there is still no appropriate central certification scheme that has been accepted and put into use by the NDT community.

Conclusion

At present, it does not appear that key U.S. industries will reach consensus regarding central certification or to implement major improvements, such as consolidation of current schemes that overlap. It is still the opinion of many involved in the NDT community that the ultimate solution will be agreement by industry to embrace a “single” standardized certification system that will be fair, consistent, and appropriate for all. There is continuing concern about the cost and whether such a system will work for all industries.

Compendium

Current or past certification related programs being used in the United States (partial list):

- Recommended Practice SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing

- ASNT Level III Certificate Program with examinations

- ASNT Level III Certificate Program without examinations Grandfathering (Note - no longer active)

- ASNT Central Certification Program (ACCP) by examination (Level II and Level III)

- ASNT Central Certification Program (ACCP) by Grandfathering (Level II and Level III) (Note - No longer active)

- NAS 410 - Certification and Qualification of NDT Personnel (National Aerospace Standard)

- ANSI/ASNT ILT-PQ-2010 In Line Inspection Personnel Certification

- ANSI/ASNT CP-189, ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel

- ANSI/ASNT CP-105, Nondestructive Testing - Qualification and Certification of Personnel

- ANSI/ASNT CP-106 Standard for Qualification and Certification of Nondestructive Testing Personnel

- ASNT CP-107 ASNT Standard for Performance-Based Qualification and Certification of Nondestructive Testing Personnel

- NSTR-99 – Qualification Requirements for NDT Personnel (Military Standard)

- ATA 105 – Guidelines for Qualification of NDT Methods Personnel (Air Transport Association)

- DOT 49CFR Part 192 – Operator Qualification Rules (Department of Transportation)

- EPRI NP-5658 Assessment of the IGSCC Training and Qualification Program (Electric Power Research Institute)

- EPRI Qualification of Performance Demonstration Initiative (PDI)

- AWS Certified Welding Inspector (CWI) (American Welding Society)

- AWS Certified Welding Supervisor (CWS)

- AWS Certified Radiographic Interpreter (CRI)

- ASME Nondestructive Examination and Quality Control Central Qualification and Certification Program (ANDE)

- ISO 9712, Non-destructive testing - Qualification and certification of personnel

- EN 473, Non-destructive testing - Qualification and certification of NDT personnel - General principles

- API 1104: Standard for Welding Pipelines and Related Facilities

- NAVSEA technical publication - Requirements for Nondestructive Testing Methods - T9074-AS-GIB-010/271

- NAVSEA 250-1500-1 Welding Standard

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!