Magnetic particle inspection is widely used to inspect production parts, parts in service and for periodic inspection of structures such as bridges, aircraft engines and landing gear. The method was originally developed in the late 1920s and through the years has been improved to speed up the inspection of production parts and to increase test method sensitivity.

This method always consists of two things: the application of a magnetizing force along with an indicating medium. How the force is applied and the type of indicating medium that is used varies, but the basic physics is always the same.

Magnetizing Forces

Most of us can remember playing with magnets as kids and may even have seen a grade school demonstration in which iron particles were sprinkled on sheet of paper that was held over a magnet. The particles formed a football shaped pattern between the magnet’s poles. If you think of that pattern representing lines of force and substitute an iron bar for the paper, then magnetic particles will be drawn to any discontinuity in the part that crosses the lines of force. This is the most basic form of magnetic particle inspection; a discontinuity at or near the surface of a ferromagnetic part will cause a disturbance in the flux field around the part. The disturbance in the field creates a north and south pole, which attracts magnetic particles. In fact, permanent magnets like the one used in the grade school demonstration are still used for nondestructive testing when other forms of magnetizing force cannot be practically used.

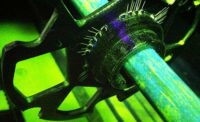

Electromagnetic yokes are more convenient than permanent magnets, but function the same way. These devices are most frequently used for field inspection and are electromagnets with articulating legs which transfer magnetizing current into the part or test area they are placed on. When the yoke is energized, the legs create a magnetic field in the part. Yokes can be alternating current (AC) or direct current (DC), with AC magnetization causing slightly more particle mobility whereas DC current offers the ability to detect indications slightly under the surface of the metal. When using mag particle yokes, magnetization in two perpendicular axes is needed to thoroughly inspect a part. It is also necessary to “walk” the yoke along a part, magnetizing and inspecting the area between the legs, before moving to the next area.

Permanent magnets and yokes are inconvenient for inspection of an entire part, as the area that can be inspected is only between the legs of the magnets. When inspection is performed during production, it is common to use low voltage, high current power supplies such as wet magnetic particle benches to induce fields in all or most of a part.

Any conductor that carries a current also has a magnetic field around the conductor, and the “Right Hand Rule” is the easiest way to visualize the field. When a part is clamped between a headstock and tailstock on a wet mag particle machine, the part becomes a conductor. If you point your right thumb in the direction of current flow, your fingers represent the lines of force. When a discontinuity intersects your fingers it also intersects the lines of force, and will attract magnetic particles. Parts ranging in size from small fasteners to large valve bodies are tested using this method, but large parts such as valve bodies weighing thousands of pounds are tested using large power packs rather than wet benches. Just as with yoke inspection, it is usually required that the magnetic field be turned ninety degrees to detect discontinuities in all orientations.

Turning the field is accomplished by wrapping a coil around the part, and the coil is generally three to five turns. The “Right Hand Rule” applies with coil inspection just as it does with contacts, but a longitudinal field is induced with a coil. Longitudinal fields exit parts and can be measured, which is why coil inspection is usually performed after head inspection.

Indicating Media

Magnetic particle powders are available either as dry powder or as particles that can be suspended in a liquid bath. Dry powder is most often used under visible light and is chosen when it is not possible to darken the area or where wet materials are inconvenient. Dry particle powder is frequently blown onto parts using a powder bulb.

Wet particle materials may be suspended in oil or water and frequently have a fluorescent dye bonded to the particles to improve indication detectability. Oil baths should use high flashpoint, low odor, low fluorescing oil that is compatible with the mag particle process. Kerosene or other low flash petroleum-based liquids should not be used as particle carriers as they can be dangerous to operators, equipment and parts, and the fluorescence of the oil can mask indications.

Water baths require that a wetting agent be mixed with the magnetic particles to improve surface wetting and to help the particles remain in suspension. Whether oil or water is used, baths must be kept agitated to keep the particles in suspension and the particle concentration should be measured daily using a settling tube to ensure the particle concentration is within the acceptable range.

Fluorescent particle materials are visible under black lights that operate in the 365 nm range. These lights should provide a minimum UV-A intensity of 1,000 µw/cm2 when held 15 in / 38 cm from the work surface, and the visible white light in the inspection area must not exceed 2 ft-candles. The traditional mercury vapor UV lamps which have been used for decades are no longer manufactured and have been replaced by high output LED lights.

Discontinuities vs. Defects

Care has been taken throughout this discussion to refer to discontinuities or indications rather than defects, and the same care should be exercised when specifying magnetic particle inspection since every artifact that causes a mag particle indication is not a defect and there should be some consideration to what actually makes parts fail.

Unfortunately, it is still common to see specifications that say “100% Magnaflux inspection required. No cracks allowed.” This specification should be avoided. Magnaflux is a brand, and while it is synonymous with the inspection method, it is not the method. More importantly, this specification assumes that everyone agrees upon what constitutes a crack. Cracks have length, depth and location details, which should be included when developing specifications for inspection. The spec writer should consider what might make a part fail. It isn’t always possible to fatigue test parts, but this is the best way to develop inspection specifications. Modeling can help with this task, but common sense and experience should be used when other options are not available. Specifying the size and location of discontinuities that are cause for rejection is as important as specifying the tolerances on dimensions.

Despite being a technology developed in the 1920s, magnetic particle inspection is still widely used today because of its simplicity, speed and effectiveness. The materials and equipment needed to perform a proper inspection are relatively inexpensive and comparatively little training is needed to prepare an operator to use the magnetic particle method.