The Advantages of Adaptive Ultrasonic Phased Array for Inspecting Composite Aircraft Components with Complex Geometry

Ultrasonic phased array technology is widely used to inspect composite components in aircraft.

Inspecting composite floor beams using phased array.

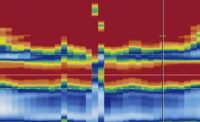

The process of adaptive ultrasound. On the left, the front wall of the component appears as a curve; the back wall is not detected, showing that the part was not properly inspected. On the right, after multiple iterations, the beams are corrected in such a way that the front wall is a line and the back wall is properly detected. As a result, all indications located in the component can be properly detected.

The three steps of the adaptive process.

L-shape component inspection.

Inspecting uniform varying radiuses with (left) and without (right) adaptive focusing.

Inspecting non-uniform (weighted) varying radiuses with (left) and without (right) adaptive focusing.

Misalignment with (bottom) and without (center) adaptive focusing.

Composite components are used extensively in the design of new generation aircraft. During manufacturing, the aircraft’s structural components must be inspected with ultrasonic technology to ensure their integrity. However, this inspection can be challenging. Some components have very complex shapes where the surfaces are constantly changing. In addition, some manufacturing processes have loose production tolerances that result in components with slightly different shapes than the original design. In these varying circumstances, complex automated scanners are commonly required for ultrasonic inspections to maintain an ultrasonic beam normal to the component’s changing surface. However, even then there is no guarantee that the ultrasonic beams will remain perpendicular to the part’s surface.

The use of an adaptive ultrasonic method with phased array is a solution to inspecting components with complex shapes. This setup locally applies a correction to the ultrasonic beams, helping ensure the beams propagate normal to the surface at each inspection position.

Ultrasonic phased array

Ultrasonic phased array technology is widely used to inspect composite components in aircraft. The main advantage of the phased array technique is the use of a large array where the ultrasonic beam is generated by a group of elements using time delays (focal laws); the beam is then multiplexed over the length of the array. This electronic scan enables coverage of a large area while maintaining high resolution. In addition, modern electronics are scalable and can drive multiple phased array probes in parallel for increased productivity. Because of these benefits, phased array technology is widely used by most of the composite component manufacturers worldwide.

The process of generating ultrasonic beams using predefined focal laws is deterministic. This means that the time delays are calculated using a known geometry, a measured distance between the probe and the component, the curvature of the component, probe orientation, etc. During the inspection, the beams are generated based on the model input during setup and cannot adapt to changes in any of these parameters. For most flat or nearly flat components, the effect is negligible. However, this limitation is important when the component being inspected has a severe curvature or irregular tolerances. In these instances, an adaptive ultrasonic phased array solution is required.

Adaptive ultrasonic phased array

Adaptive ultrasound is an acquisition strategy that has gained popularity in the aviation industry because it facilitates ultrasonic inspection of the increasingly complex parts manufactured for new aircraft.

Adaptive ultrasound enables the transmission of a wave front parallel to the surface of a part with complex geometry. The adaptive ultrasound process can be divided into three steps. First, a plane wave is transmitted using all available elements on the phased array probe, and the elementary A-scans are recorded. The second step is an iterative process that adapts the front wave to the geometry of the part. This process adjusts the delays for each transmission event until a convergence criterion, based on the time of flight from each element, is reached. Once the convergence criterion is reached, the third step is to generate summary A-scans, just like in a standard phased array inspection, using the elementary A-scan received from the last transmission event.

Benefits of adaptive phased array

In the aviation industry, adaptive ultrasound helps address the following inspection challenges:

- Components with varying radiuses and twists

- A manufacturing process leading to components with non-uniform radiuses (weighted radius)

- Misalignment of the phased array transducer relative to the inspected part

In this section, we illustrate the benefits of adaptive phased array using three examples. The first two examples were performed on an L-shaped component. The radius of the component was inspected using a 5 MHz curved phased array probe with a local immersion probe holder. In these two examples, the radius of the component varied from 0.2 inch to 0.5 inch over its length, but the first component has a uniform radius and the other has a non-uniform (weighted) radius. Delaminations are embedded in the components at different positions. Scans were performed with and without the adaptive algorithm.

The result shows the C-scan mapping of the components’ radiuses. In both cases, all the delaminations are clearly visible with the adaptive algorithm, while the C-scan without the adaptive method has zones containing undetected flaws.

In the third example, a 5 MHz linear array probe was intentionally misaligned. The test was performed in an immersion tank. We can see the effect of a misaligned phased array probe, while the C-scan obtained using the adaptive method corrected the beams, enabling the components to be properly inspected.

Considerations

Adaptive ultrasound can be implemented in such a way that it does not impact productivity when compared with conventional phased array. In addition, a live data display is required during the inspection, so the algorithm for adaptive ultrasound has to be directly implemented in the inspection instrument to obtain real-time data visualization.

Conclusion

Adaptive ultrasonic phased array is an excellent method to improve the ultrasonic inspection of composite components with complex shapes. The ability to adapt the ultrasonic beams to the component’s actual shape brings more confidence and reliability to the inspection process and reduces the quantity of rescans, improving productivity. Also, compensating for the misalignment of the phased array probe minimizes the need for extremely precise mechanics.

Used manually or with a high-performance scanner, this method enables users to quickly inspect large surfaces with high resolution because its implementation does not compromise productivity. Adaptive phased array is used successfully for complex aircraft components inspection, and it is becoming common in other industries, including automotive, energy, and petrochemical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!