NDT Flaw Detection 101

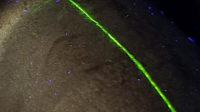

We’re always faced with deciding which nondestructive testing method is the most appropriate for detecting a specific flaw type.

FPI Indication

According to ASTM E1316-17a and NET.net, a flaw is defined as ‘‘an imperfection or discontinuity that may be detectable by nondestructive testing and is not necessarily rejectable.” A flaw is also something that can occur in various sizes, shapes, orientations, locations, and can even only be isolated to a tiny portion of the material properties within a material volume. Flaws can be also be naturally occurring or can be introduced by material processing or finishing. So, with this wide range of definition and generation possibilities, there is also a lot to take into consideration when understanding NDT capabilities for detecting flaws.

NDT Level IIIs are always faced with deciding which nondestructive testing method is the most appropriate for detecting a specific flaw type. Is the area of interest internal or external? Is the material metallic, ferrous or nonferrous, composite, single layer, multilayer, dual material? Is there proper access to the areas of interest to allow for detectability? Are the standard NDT methods appropriate or does an advanced method need to be investigated and deployed? All of these things need to be considered to ensure that the flaw can be detected.

Visual Indication

The first consideration needs to be the question of location, is the flaw internal or external? Determining this will quickly help you focus in on likely options and to eliminate several others. External flaws are typically found using visual testing (VT) and aided visual testing methods like liquid penetrant testing (PT), and magnetic particle testing (MT). Additionally, electromagnetic testing (ET) and ultrasonic testing (UT) can be used for detecting tighter external flaws. For internal flaws, radiographic testing (RT), ET, and UT are the primary methods for detection. There are advanced NDT methods such as phased array ultrasonic testing (PAUT), laser interferometry (LI), acoustic emission (AE), resonance inspection (RI), and several others that can also be considered.

The question of ferrous and non ferrous is only pertinent for the selection of PT or MT. PT can be used on both, but MT can only be used when a material is ferrous. MT is usually the best choice when there is a choice between these two options. This is based on processing time and not on sensitivity.

Proper inspection access to the areas of interest is next to consider, but this one can be tricky. For external flaws, line of site must be present. There are some exceptions to this when using ET or UT, but this is typically the deciding factor. For items without line of sight, an internal method should be used.

Once you have determined location(s) and area(s) of interest, the last thing to understand is the desired sensitivity of a selected inspection. Many things can influence the sensitivty of inspections, but some of the main items to consider are: geometrical complexity, material density, surface roughness, and accessibility. I am sure that specific applications can and will have a longer list of items, but these four things should get you pretty close to selecting the right NDT method. Let’s look at each of these four items a bit closer:

Geometrical complexity – If you had a simple rod, bar, or panel, something that you can access from just about any direction, then your flaw detection method will not be driven by geometrical complexity. But, if you only have access to a single side of your test piece, or if the access you do have is smaller than the smallest NDT probe you have available, then you will need to select your method based on what the geometry will allow.

X-Ray Specific Area of Interest

Material density – Density and thickness of material can be critical to flaw sensitivity. If your material is very dense and is also quite thick, even the best RT systems can be challenged. Distinushing a very small flaw can be nearly impossible in this situation. The same can be said if the density is disparate or an agglomeration. From simple concrete aggregate to advanced materials used for additive manufacturing powder elements can cluster and segregate causing an area to possibly be materially sound, but greatly reducing sensitivity to a flaw.

Surface roughness – The surface is where many of the inspections need to contact, so a rough surface makes for a difficult inspection, or no inspection at all. UT and ET need to have good contact, so a rough surface can take those methods right out of consideration. PT and MT can cope a bit better than UT and ET, but a rough surface can cause poor interpretation and false positives. If the surface roughness is part of the design or the best that can be done, RT or a full body inspection like resonance are really the only options.

X-ray Broad View

Accessibility – As with surface roughness, accessibility can quickly rule out UT and ET because you have to be able to have adequate probe contact. PT and MT are usually pretty good at limited areas of accessibility, but remember that line of site with the area of interest must be possible. Accessibility can also be difficult for even X-ray and tomography.

As you can see, if you are in a situation where you need to select a method to find a flaw, there is plenty you need to understand before making a decision. Each method has its own strengths and weaknesses and no flaws are created equal. Be sure to always think about what each method provides, how each method works, and most importantly how sensitive the method will be for your detection needs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!