How Machine Vision Cables Impact Machine Vision Performance

Choosing high quality cables is your best approach for long-term productivity and consistent imaging data.

Over molded and angled connectors are shown here.

Machine vision cables play a central role in the overall performance of machine vision systems. Those in need of robust, reliable vision results are wise to use the highest quality cables. Far too often, machine vision cables are seen as a place of potential cost savings on system design.

It’s important to understand the difference between high quality machine vision cables and consumer-grade or even cheap, discount cables. For today’s machine vision systems to deliver the desired result, maximizing the full return-on-investment potential, and even just functioning correctly, the right quality cables are imperative.

In our last Quality article, we discussed the value of selecting the right machine vision interface. Once you have selected your interface, choosing high quality cables is your best approach for long-term productivity and reliable, consistent imaging data.

The Consequences of Using Low Quality Machine Vision Cables

The most robust machine vision system out there will perform terribly when low quality cables are used. All image data flows through the cable—the funneling of this data must be carried out by a high quality cable capable of protecting the integrity of the data, or poor performance will result.

One of the most common ways that cheap cables underperform is through their susceptibility to interference. Lights, motors, and other power-consuming equipment that are common in industrial environments can cause signal interference. When a cable experiences interference, it creates crosstalk that degrades image quality. This is typically caused by the insufficient shielding in low quality cables.

Cables that aren’t properly industrialized are also vulnerable to physical damage. This is especially true near the connectors, where cables are particularly delicate and small amounts of damage can cause the entire cable to stop working. This could arise from normal handling or storage, or it could be caused by constant pressure due to the positioning of the camera itself. Regardless, physical stress can easily cause damage near cable connectors which can quickly lead to a defective cable and unreliable data.

Some applications require specialty cables, such as military applications or those exposed to harsh chemicals. Given these harsh environments, cheaper cables may simply not withstand these extreme demands or maintain full compliance. However, no matter the application, all cables should receive performance testing to ensure they’re able to deliver on their promised performance. Cheap cables will likely receive infrequent performance testing, meaning you could be left with a defective or underperforming cable right from the start.

There are many consequences to using poor quality cables. Although it may happen in different ways, the end result is a machine vision system that’s incapable of achieving its full potential or even performing well enough for the task at hand. In the industrial and scientific sectors, cables are not a source of smart cost savings and should be carefully considered so as to choose the highest quality to meet application requirements.

What to Look for When Selecting High Quality Machine Vision Cables

When investing in a machine vision system, any savings on lower quality cables are paid for many times over with lower performance. Given the overall cost of a machine vision system, it’s important to ensure the final process of data transfer doesn’t create data loss. But even when you know your application should be using high quality cables, it may be difficult to ascertain which cables are of the highest quality.

For those in search of robust cables, there are a few quality indicators to look for in machine vision cables.

Strong, Industrialized Cable Shielding

Industrial environments can be harsh. They may contain harsh chemicals, temperatures, or at the very least a large amount of power-consuming equipment that’s hard on cables. Machine vision cable shielding is a critical component of a high quality cable. The outside of the cable should have some form of industrial shielding, such as PVC or TPE jacket materials, but the inside of the cable is just as important.

High quality machine vision cables will have more levels of shielding inside the cable. Individual wires may be shielded or even wrapped in an aluminum mylar material to protect the signal from interference. Some cables may have a tin-copper braid for even further protection of the internal wires. This type of layered internal shielding is an excellent indicator of durable machine vision cables.

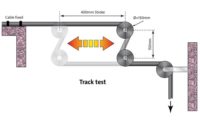

Cable Connector Protection and Position

Not every machine vision system is mounted horizontally in a wide-open space. Often, machine vision systems deal with tight space constraints or must be mounted at an angle or vertically. In these instances, regular machine vision cables will be susceptible to damage from the constant stress put on the cable near the connector. This kind of damage from prolonged stress can quickly degrade or destroy a cable’s ability to transfer data. Angled connectors, available in any angle you could need, eliminate the stress placed on the cable to extend its lifespan and protect the integrity of data transfer.

Similarly, low quality cables are often unprotected near the connectors, which is the most delicate part of a cable. High quality cables, whether they’re angled or not, should have thick, plastic protection, often referred to as over-molding, around the connectors and the end of the cable. This makes them tamperproof and resistant to physical damage. Over-molding helps prevent unreliable data transfer and poor image quality by protecting a vital part of the cable.

Robotic machine visual systems depend on high quality cables.

Frequent and Transparent Cable Performance Testing

All components of a machine vision camera, such as the lenses and lighting and frame grabbers, are required to undergo 100% performance testing. Machine vision cables, however, are not required to pass this rigorous quality assurance. If your application requires uncompromised reliability and consistency of high quality data, then you will be well-served to look for cable performance testing to ensure the cable you purchase can deliver on the expected performance.

Often, these cables are tested for near-end cross talk and far-end cross talk. Both measure noise levels near each connector, as well as return loss, which measures how much signal is returned down the length of the cable and back during testing. Attenuation is also tested, which is the noise factor that causes the loss of signal strength. When cables undergo 100% performance testing, especially when it involves the tests mentioned above, it’s a great indicator that the cable is of the highest quality and will perform reliably.

Cable Life Expectancy Quantifications

Quantifications of life expectancy for machine vision cables are highly valuable. First and foremost, it immediately gives you an idea of how much your machine vision cables will cost over time as they need to be replaced. With this information, it may be immediately apparent that the cost of replacing low quality cables exceeds the investment in higher quality cables based on compromised, unreliable data as well as the frequency and unpredictability of replacement, which affects downtime.

Life expectancy quantifications are a good sign the cable you’re purchasing has been thoroughly performance tested, further ensuring cable quality. They also allow you to pinpoint the most profitable times to replace cables during normal maintenance cycles, a further justification for the additional cost of higher quality cables. The presence of life expectancy quantifications also signals the manufacturer’s confidence in the quality of the cables and in their ability to withstand specific environments for the given time frame.

High Quality Machine Vision Cables Maximize Performance

When investing in a machine vision system, cables should not be viewed as a source of cost savings. All image data flows through the cable—a low quality cable will degrade image quality and harm system performance. To optimize machine vision system output, the highest quality cables should be used to achieve the system’s full productivity potential and maximum ROI.

The four quality indicators mentioned in this article are key, but they are far from the only things to look for in a machine vision cable. Diving deeper into cable construction and applications yields even more attributes that a high quality cable will have. Q

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!