Manufacturers React to the Coronavirus

This survey explains how manufacturers are dealing with the pandemic.

In these strange times, every industry around the globe has been affected by the coronavirus. And manufacturing is no different.

As one manufacturer said, “Every day is a new day with a new supply chain challenge to overcome.”

This comment comes from a Manufacturing Industry survey conducted by Clear Seas Research in conjunction with Quality Magazine. The survey looks at how the coronavirus is affecting manufacturing. The research addresses these areas:

- Industry concern related to the pandemic and the impact on business and the economy

- The impact of the pandemic on manufacturing

- Measures being taken to keep employees, customers, and others healthy/safe

- How industry professionals are managing current business activities and planning for the future

Here’s what respondents have been saying:

“I’m an automotive supplier to the OEMs Tier 1’s. With the OEM assembly plants shut down, the tier 1’s are shut down. Although we are operating under the essential business clause, our automotive sales are significantly down due to our core customers (automotive tier 1’s) being closed. I will likely receive a $0 annual bonus this year due to this decline. To put it in perspective my 2018 annual bonus was $32,000. That’s a big loss to my personal pay.”

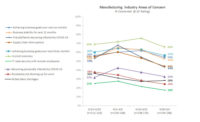

Overall, the top areas of concern for manufacturers were: the current economy (69%), achieving business goals over the next three months (60%), and achieving business goals over the next six months (56%). Other concerns included supply chain disruptions, business stability over the next 12 months, family or friends becoming infected, and employees not showing up for work. Lower on the list of concerns were: skilled labor shortages, personally becoming infected with COVID-19, and IT cybersecurity with remote employees.

In terms of active business, 67% is still on schedule. Twenty-six percent is delayed, and 7% is cancelled. Planned business looks similar, with 63% on schedule, 31% delayed, and 6% cancelled.

Sixteen percent said new business development activities had increased, 20% saw no change, and 64% saw a decrease. In terms of business spending on equipment and services, 8% saw an increase, 29% said there was no change, and 63% saw a decline.

In terms of the pandemic, keeping employees healthy is, of course, a priority. Here are the top five actions used to do so:

- Encouraging hand washing

- Promoting social distancing

- Providing hand sanitizer/antibacterial soaps

- Increased frequency of cleaning/sanitization procedures

- Eliminating/reducing employee business related travel

There were a range of approaches, including: giving employees the option to work from home, providing personal protection equipment, requiring employees to work from home, delaying projects, splitting workforce shifts to reduce number of employees onsite, temporary closing of business, purchasing new technology for remote workers, cancelling projects, increasing time between shift changes, increased health related communications, eliminating vendor/customer visits, reducing/eliminating face-to-face meetings, and giving the option to not work. Only 2% said they hadn’t done anything.

Not surprisingly, there are a few activities of greater focus today relative to six months ago. The top one is incorporating additional health/safety procedures into business plans. Others include attending more webinars, reading more industry publications (both digital and print), investigating new technologies for future business applications, and learning new skills.

The online survey was sent to BNP Media subscribers and fielded March 24-26, 2020.

As one respondent said, “Timing is critical. To date, the strategy changed daily.”

To download the full manufacturing report for free, visit

www.clearseasresearch.com/product/manufacturing-industry-perspective-on-the-challenges-of-today/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!