Producing Additively Manufactured Parts

The future of additive manufacturing will include an increasing number of production applications.

Additive manufacturing has moved far beyond its prototyping roots. Today, additive for production applications is a growing area of interest.

Dr. Pradeep Bhattad, business development manager of ZEISS Additive Manufacturing Process and Control at ZEISS Industrial Quality Solutions, is collaborating with Oak Ridge National Lab’s Manufacturing Demonstration Facility on this exact topic. His team is working on overcoming quality related challenges and moving the metal AM process from prototyping to production.

Dr. Bhattad focuses on the quality aspect of 3D printed parts, what he describes as an exciting and important area of additive. As he says, 3D printers are not “plug and play machines. There’s a lot of variance in the process.”

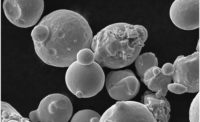

And especially for production scale applications, it’s important to get the quality issues under control. The porosity, surface features, and mechanical properties all need to be controlled, he notes. For example, it would be necessary to find the origins of porosity either from process variables or raw materials. Once this is done, manufacturers can figure out what they need to do to eliminate issues.

For example, this may mean developing procedures or altering an additive “recipe” for a given printer or using nondestructive technologies to examine parts.

When it comes to additive manufacturing production, Dr. Bhattad says most companies today are not looking at high volumes. Industries such as aerospace, automotive, and oil and gas are currently just producing a small number of parts that can’t be produced any other way. For these low volume applications, additive works well.

The industry is changing, however. He notes that printers are getting much cheaper, as are raw materials, so achieving production scale is becoming more realistic.

In industries such as medical, additive has been hugely influential. With medical implants, the additive industry has taken off. And not just for custom implants, he notes. It’s also becoming increasingly common for standard sized implants produced using metal AM as well as hearing aids produced using polymer AM. Additive provides a scale and cost advantage for these complex designs.

Additive Today

Today’s additive process may go something like this. Optimize print parameter for a given material and printer initially by building test coupons, then graduate to creating an actual prototype. This step again requires refining of process parameters for printability, support strategy, surface roughness etc. In order to scale up to production scale, we also need to consider post-print processes such as depowdering, support removal, heat treatment and surface finish. Finally, it would be time for quality inspection, perhaps with a CMM, as would be done with a traditionally manufactured part.

During this process it would be important to consider factors such as the variability of powder, the machine undergoing maintenance, and stresses on the part as it is being printed and deformation as a result of heat treatment.

“What we are working on here,” Dr. Bhattad says, “is how do we connect all these isolated islands and develop an integrated quality solution.”

He’s looking at all of the factors involved, and “which one had the maximum impact and what I care about most, what tools I can use to keep my production under specification.”

In the partnership with Oak Ridge National Laboratory, his team is working on integrated quality control, looking at powder to final part using different multi-scale multi-modal measurement as well as in-situ monitoring.

For example, although there are countless tools available, they are looking at finding the optimum tools to control the process before the part comes out of the printer.

Rather than looking at isolated steps in the process, the team is working on an integrated approach. The development cycle for a production scale process can be dramatically cut down using this approach. For example, he says looking at the issue in a holistic way can eliminate a few iteration loops of the cycle, or change a process from six months to perhaps three or four weeks.

“We’re definitely seeing an advantage of this approach on projects so far,” he says. Since partnering with Oak Ridge last October, they’ve completed five successful projects.

And since his work is focused on the quality aspect, he’s looking at the requirements and considering what new tools are needed to solve problems.

Previously additive manufacturing was known for the ability to create parts with complex geometries that couldn’t otherwise have been made. And while complex geometries are still an additive advantage, there are a growing list of reasons related to material. In the past couple of years, Dr. Bhattad notes that the printing process has allowed for changing material properties by controlling micro-structure. For example, when printing with a steel grade 316 powder, by controlling print parameter it would be possible to make that material have higher wear resistance on the edges and fatigue resistance properties in the bulk or even behave like another alloy. This could create a material to “behave in a way that no other manufacturing method would produce,” he explains.

But for all the advantages of additively produced parts, there has been one factor standing in the way.

“Quality has been a hindrance why these parts haven’t gone into production,” Dr. Bhattad says. “It’s hard. It’s a multi-headed hydra kind of problem.”

The only way to solve this problem is to look at it in a holistic way, he says, rather than just using one technique to look at one issue in isolation. “Right now, industry needs it,” he says.

And Dr. Bhattad and others are hard at work on solutions for the industry. As he says, the idea is to “learn about the challenges, be ahead of the curve, and be ready with quality tools.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!