Inspection

Quality and Process Control for the Dispensing Process

For Many Applications, Good Robot Programming is an Art.

Dispensing, as an automated manufacturing process, has become more and more popular and common in automotive, electronics, medical devices, aerospace, packaging and many other industries. The materials dispensed can serve a wide range of purposes such as structural joining, corrosion resistance, seal, noise, vibration and harshness (NVH) reduction, part protection, durability enhancement, thermal dissipation, and bonding.

In a mass production environment, a desired well-controlled dispensing process is supposed to produce the right amount of “glue” at the right location on parts in a consistent way with minimum production downtime. However, if a candid conversation can be engaged with experienced members of the manufacturing community, it will show that the reality has long been quite a deviation from this beautiful desire of well-controlled beads. There are many reasons for this, but fundamentally dispensing is, relatively speaking, a new manufacturing process, and there has not been a widespread wealth of experience and knowledge shared across the industry to deal with many inherent variations.

A few typical sources of variations and contributing factors:

- Part-to-part variation. This kind of part-to-part variation can be in the lateral direction and/or the vertical direction. Sometimes, this variation can be big enough to cause large quality spills. For example, with the closure panel hem seal application in automotive door assembly, a few millimeters of lateral part variation from the stamping process can cause either void in hem seal or squeeze-out, both of which will cause a pass-through failure in the paint shop. Another example is the windshield polyurethane dispensing. The shape of the glass can have up to ±4mm difference batch to batch. The high-profile triangular polyurethane bead dispensing requires a constant distance between the nozzle tip and the glass surface along the entire bead path. As a result, frequent robot program changes become a common practice, whether it is right or wrong, to deal with this kind of variation.

- Part fixturing inconsistency. A repeated process requires repeated part location in the fixture nest. However, this is not always as easy as people would think. For example, the vacuum suction cup is a common method for fixturing flexible or fragile parts. However, parts from the stamping shop typically carry a thin film of oil, which is a big cause of suction cup failure over time.

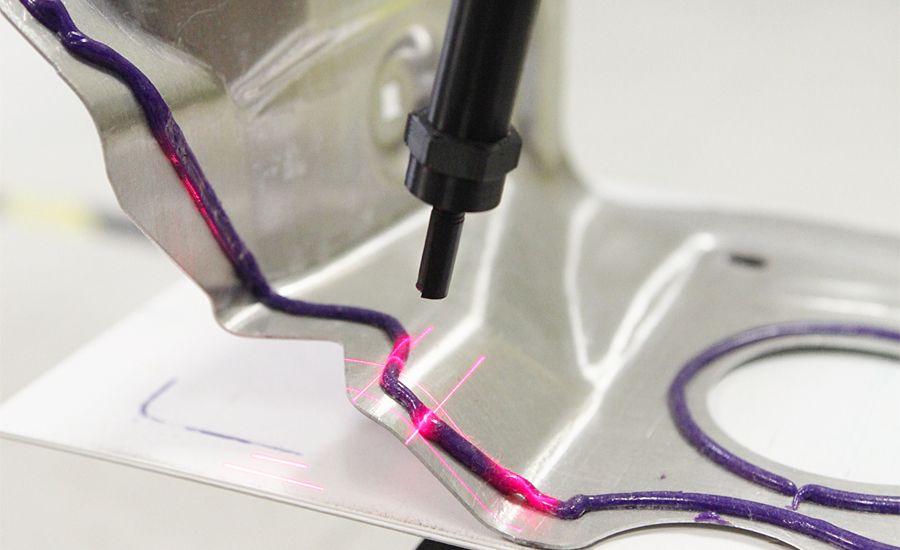

- Robot programming. For many dispensing applications, good robot programming is an art. How far do we want to keep the nozzle away from the part? How fast do we want to run the nozzle around corners? For a 90° sharp turn in the confined 3D space, how do we keep a good velocity between the nozzle tip and the part to avoid the nozzle dwell which could cause a big blob? These all require a very good robot programming skillset, which nowadays is a rare asset.

- Dispensing material property variation. The viscosity is one of the most important material properties which can present big variations in the production environment because it is highly dependent on the material temperature. More viscous materials tend to flow less, which causes less volume of material dispensed under the same dispensing setup. Air bubbles can be introduced during a barrel change if not handled carefully. These air bubbles, when dispensed, can cause gaps or neck-downs in the bead path.

- Limitation of current dispensing systems. The communication and response latency is a practical limitation of even the state-of-the-art dispensing systems. The communication commands sent from the robot can typically take tens to hundreds of milliseconds for a dispenser to respond. And for a mass production line, robot speed can be up to 800 mm/s. At this speed, every millisecond counts. Another common issue with the dispensing system is the material drooling after the gun is turned off due to the liquidity of the material. This problem is being addressed by many advanced dispensing equipment makers through their clever “tip-seal” or “snuff-back” nozzle designs.

- Improper system maintenance. In the production environment, lack of a good process to maintain the dispensing process is not uncommon. For example, with a two-part Epoxy application, the nozzle is typically made of plastic for easy disposal with a long mixing tube to satisfy sufficient mixing before dispensing. If not handled appropriately, the frequent nozzle replacement process can easily change the location of the nozzle tip.

To address this challenge, the manufacturing industries have been striving for years for a robust quality control solution which can reliably sort out bad parts without causing much production downtime. Traditionally, 2D vision has been tried extensively. However, 2D is based on the contrast between the foreground and background in the grayscale images taken for detection. This contrast varies a great deal in the production environment, and many times, the bead color is similar to the part color (black on black or gray on gray) and there is not even a good contrast to start with. This has made 2D vision very temperamental for this dispensing application. Typically, 2D vision systems are implemented as a post-inspection process. This adds production cycle time, which most mass production environments don’t have the luxury of.

- The rotating mechanism is bulky and not very fast in response to sharp turns at high robot speeds.

- The performance is highly dependent on the integration and the ease of the job.

What the industry craves is a robust 3D solution that provides a 360° view of the bead regardless of the dispensing direction. A solution that is “on the nozzle” that doesn’t require any additional floor space or add cycle time. A solution that can inspect the bead location in reference to part features. A solution that can overcome part to part variation, part fixturing inconsistency, complex robot programming and dispensing material variation. A solution that provides a robust quality control measure to sort out good and bad parts from different bead dispensing processes.

However, if the dispensing system is poorly engineered or commissioned, or the dispensing process has too many inherent variations, constantly failing parts with a robust quality control method alone won’t help manufacturers much.

A good process control strategy is indeed necessary to deal with these typical inherent variations and keep the dispensing processes producing quality parts. Some examples of the process control capabilities for considerations are:

- Automatic repair of certain dispensing defects such as skips or neck-downs.

- Automatically check the material build-up around the nozzle and run nozzle cleaning accordingly.

However, when the bead volume is trending or the bead location is trending undesirably, an Artificial Intelligence (AI) enabled adaptive process control capability to counter these trends will be a game changer. This process control will automatically adjust the dispenser or the robot programs to deal with these inherent process variations accordingly. All of this can only be possible with a real-time robust 3D inspection system which can work closely with other automation equipment, such as different robots and dispensers, with a well-controlled latency.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!