Measurement

Multisensor Metrology Systems: Quality’s Swiss Army Knife

Always have the right tool for the job.

All Images Source: OGP / Alex Shortt

Modern manufacturers are consistently creating parts that are more complex than ever. Intricate, three-dimensional parts with a multitude of features – all with their own critical dimensions – are the norm.

In the past, manufacturers would measure their parts using traditional coordinate measuring machines (CMMs) outfitted with touch probes. Traditional CMMs do provide accurate measurements, but precision manufacturing requires a variety of precision inspection solutions, and today's most precise manufacturers rely on multisensor metrology systems to deliver accuracy for process monitoring and control.

Today’s manufacturers know the importance of having the right tool for the job. Multisensor measurement systems offer a variety of sensor technology tools, allowing for efficient and accurate results in the measurement process – they truly are the Swiss army knife of the quality or inspection department.

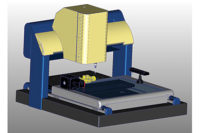

Multisensor metrology systems provide the advantage of complete 3D measurement data from a single measuring machine. A modern multisensor system combines optics, contact probes (touch trigger and scanning), laser and micro-probes, along with advanced lighting and motion control, for total part characterization. These systems offer highly accurate measurement results in a fraction of the time it would take to do on separate measuring systems, and in a fraction of the space required for multiple measuring systems.

Optics: The Core Of The System

Modern multisensor metrology systems offer strong optical systems at their core. Optical metrology is fast and does not require physical contact with the part being measured. Video measurement provides high accuracy and repeatability when detecting features, orienting parts, and measuring edges, dimensions, angles, and surface profiles.

Manufacturers producing soft or impressionable parts – like rubber gaskets or other plastic sealing components – take advantage of noncontact measurement that video metrology provides. Manufacturers creating complex parts that have features that are either difficult or impossible to be measured by tactile sensors – like the internal geometry of a turbine blade or the surfaces of a medical implant – rely on the video metrology of multisensor measuring machines.

The two most important factors in optical image accuracy are low distortion and telecentricity.

First, optical distortion can cause changes in the geometry or form of the image of a part, which can lead to measurement errors when away from the center of the image. Advanced optical systems featured in multisensor measurement systems will significantly minimize optical distortion through careful design, manufacturing, centering, coating and assembly. Once the lens system is assembled, each unit is characterized and compensated for any residual distortion before installing the optics on the metrology system.

The second important factor impacting image accuracy is telecentricity, which ensures that the image size remains accurate even when the image is not perfectly focused. A common problem in optical measurement comes from round machined or turned parts that cause light to scatter or wrap around when measured. This “wall effect” causes the edges of the part to be fuzzy or indistinct, leading to measurement errors. A high-performance optical system will be telecentric throughout its entire magnification range, eliminating size change due to focus variations and distortion across the field of view.

Tactile Probes: For Features That Can Not Be Seen By Optics

While optical systems are highly productive, they cannot measure all features of a complex-shaped part. As part of a modern multisensor measurement system, a touch trigger probe will measure features of a part that are difficult to image, or surface boundaries that are inaccessible to optics.

Touch trigger sensors find data points one at a time, by making contact with the part, retracting, and moving to the next point. Touch probes are offered with a variety of styli lengths that allow access to the feature of the part being measured, as well as a choice of materials for the styli tip. Depending on the nature of the application, ruby, tungsten, or Teflon tips may be selected.

If a part being measured features a deep bore outside of the focus range of the video sensor, a touch probe can be deployed to reach the surface and achieve accurate measurement.

Scanning probes are similar to touch trigger probes, but are designed to make continuous contact with the surface of the part being measured to gather high-density point data for accurate profile measurements. Scanning probes collect hundreds or thousands of measurement data points as they move across the part surface.

If an application is appropriate, selecting a scanning probe over single point probing can greatly reduce both programming and measurement times, increasing measurement throughput while delivering accurate results.

For very sensitive parts that require probing as part of the measurement process, micro-probes can be added to a multisensor measurement system. Micro-probes are a variant of a touch probe, but can trigger with forces as low as 1 mg.

On a multisensor system, the optical sensor can precisely identify the location of these delicate or tiny features, and use the micro-probe to measure the features, determining if the feature dimensions are in tolerance.

Laser Sensors: Noncontact And High-Accuracy

A modern multisensor metrology system will feature one or a selection of laser sensors, which gather points from surfaces and can be used to make fast contour and dimensional measurements on a variety of materials and surfaces when scanned. Laser scanners provide accurate measurement of part features that may not be accessible by other measurement methods, including tactile probes.

Most multisensor systems are offered with a variety of types of lasers, equipped to perform high, surface, and contour measurements. A laser might be on-axis in a through-the-lens (TTL) configuration, or may be off-axis in the form of a laser pen or range sensor.

A TTL interferometric laser that is on-axis and non-triangulated, with a very long working distance, can measure deep inside recessed features that are not accessible by any other sensors. There is no offset between the optics and laser in a TTL configuration.

A side-mounted triangulation laser can achieve very high resolution even on specular surfaces that scatter laser light, while chromatic white light probes can achieve Z height measurements with sub-micron accuracy and measure surface height changes on transparent, translucent, fragile, or even liquid surfaces.

Lighting And Motion For Full Part Coverage

Any modern multisensor system will come equipped with systems that provide light that is programmable for both direction and incidence angle, illuminating parts to achieve easy, accurate measurements.

The inner rings of an LED lighting system illuminate the part from above, almost “square on.” The outer rings provide oblique lighting, ideal for chamfered edges and blended radii. By selecting different rings, users control the angle of incidence of the illumination.

Each ring is also divided into sectors, allowing users to specify the direction of the light. Any combination of rings and sectors can be selected to create just the right illumination for any application.

Some multisensor systems feature multicolored ring light systems which provide multiple colors of illumination for part measurement.

Grid projectors are also available to enhance video images of parts with little to no contrast. Glass, clear plastic, and mirror finished metal parts can be difficult to measure. By projecting a grid pattern onto the surface of a part, the optical system can quickly focus to provide accurate measurement and improved repeatability.

Fourth and 5th axis rotaries are available for multisensor measurement systems. Parts with important features on many sides can be fully characterized by using a rotary indexer.

Rotaries allow complete measurement in a single setup. Dual-axis rotaries, comprised of two rotaries mounted together, provide full five-axis capabilities for multisensor systems.

Software To Power It All

For complex three-dimensional parts, more than one technology is likely necessary to efficiently and accurately complete all measurements. Modern multisensor systems are powered by robust metrology software that calibrates all available sensors and automatically and effortlessly generates measurement routines – resulting in faster programming and run times. These software packages offer 3D CAD capability and GD&T functionality, support for regulatory compliance, and do all this with an easy to use, user-friendly interface. Many metrology software packages are built with emerging standards in mind, including Model Based Enterprise (MBE) and Industry 4.0 standards.

The best metrology software options for multisensor systems will allow for powerful routine programming in offline mode. Routines can then be deployed to systems on the floor or lab, allowing operators to initiate measurement routines without the need for extensive training.

Hikers, campers, and outdoor enthusiasts know they need a versatile multi-tool to tackle a variety of tasks. Modern multisensor metrology systems are exactly that tool for manufacturers that demand accuracy, no matter what challenge may face them.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!