Measurement

3D Scanning Fast Becoming Essential Tool for U.S. Military Manufacturers

With its precision, 3D scanning distinguishes itself from conventional measurement tools.

All Images Source: NVision

“It is an unfortunate fact that we can secure peace only by preparing for war.”So proclaimed John F. Kennedy, in a September 1960 speech emphasizing the necessity–and paradoxical nature–of military readiness: that a strong military serves as a deterrence, not a provocation, to conflict.

Manufacturing for military readiness extends beyond the initial production of arms, equipment, and technology. It also encompasses replacing damaged or outdated equipment and that lost to attrition; over time, weapon components, vehicles, communications systems– even military infrastructure–degrade, necessitating repair, replacement, or redesign.

Thus manufacturing’s contribution to military readiness should include efficiently and effectively harnessing the latest technology in its processes to:

- Continually optimize weapon and equipment design.

- Ensure manufacturing quality

- Reduce certification time.

- Rapidly create replacement parts for arms and equipment, including those sustaining damage (e.g., tanks that have driven over landmines, been hit by drones, etc.), those with manufacturing or design defects, and those that have degraded over time.

To achieve these goals, many military manufacturers are turning to 3D noncontact scanning, which offers precise measurement with virtually no size or shape limitations. Today’s scanners can capture the intricate geometry of everything from coronary stents and body armor to power generation stations and aircraft hangars. Even aircraft carriers and personnel carriers have been successfully scanned.

What is 3D Scanning?

So, what precisely is 3D scanning? At its core, it’s a noncontact, nondestructive technique for digitally acquiring precise measurement data on the shape, dimensions, and surface characteristics of real-world objects or environments. This data is used to create a computer-aided design (CAD) model of the scanned object, which can be viewed and analyzed by engineers from every angle for:

- Fast reverse engineering of parts for replacement or redesign

- Measurement/Inspection/Analysis

- Rapid prototyping or high-volume manufacturing

- Manufacturing and/or repair certification

- Analysis of the manufacturing process

The CAD file enables physical copies of the part to be produced using virtually any manufacturing process, including additive manufacturing (3D printing).

Scanning is ideal in applications where the required accuracy exceeds that provided by other measurement tools, such as calipers (aka screw gages) and micrometers, especially when the objects to be measured have complex shapes involving curvatures, grooves, bumps, and other irregular surface features.

Types of Scanners

Scanners come in diverse forms with different operating mechanisms and include laser triangulation, time-of-flight (TOF) large-area scanners, computed tomography (CT), and projected light. Each possesses distinct strengths that render it more suitable for particular applications. For instance, TOF large-area scanners excel in capturing the dimensions of sizable objects such as military transport vehicles and ships but are unsuitable for parts with internal features. Conversely, CT scanners are adept at capturing 3D representations of internal and external components, making them ideal for devices with intricate internal geometry, but impractical for large-scale scanning. Some versatile devices yield exceptional results across a broad range of applications.

Selecting an appropriate scanner (or scanning service) hinges on the application’s specific measurement requirements and desired data output. For some projects, multiple scanners may be used; for example, when scanning gun parts, a laser scanner may create the initial 3D model, which is then further refined using ultra-precise measurements from a traditional coordinate measuring machine (CMM).

Here are quick summations of some of the most prominent noncontact scanners and their capabilities:

- Computed Tomography (CT): CT scanners use X-rays to produce 3D representations of both internal and external components. Fast, with an accuracy of 0.0004 inches, they’re ideal for measuring medical devices and parts predominantly made of plastic or aluminum, as CT accuracy correlates with material density.

- Time-of-Flight (TOF) large-area scanners: These scanners excel in capturing precise 3D measurement and geospatial data from large objects or environments, such as Navy and Coast Guard vessels, military installations, etc. Other applications include measuring roads, bridges, terrain, storage facilities, utility structures, and tunnels.

- Structured Light Scanners: These scanners are ideal for measuring intricate and detailed parts. They employ white or blue light to project reference patterns onto an object’s surface. By analyzing the deflected light, the scanner calculates depth and surface information.

- Noncontact Light-based Coordinate Measuring Machine (CMM): These devices excel in capturing the 3D dimensions of objects in applications with accuracy requirements exceeding 0.0002” or 0.005 mm. Typical applications include inspecting aircraft turbine blades, testing equipment, and injection molds. CMMs boast superior accuracy compared to most measurement alternatives.

- Handheld laser scanners: Arguably the most versatile scanners for measurement and inspection, they are portable, adaptable to the application, and rapidly capture the 3D geometry of objects spanning a vast range of sizes, from the exterior of high-tech fighter jets and Humvees to landing craft propellers and smaller components like angle-of-attack sensors. They are remarkably precise and can capture 60,000 spatial measurements per second with an accuracy of +\- 0.025 mm or 25 microns, which is one-thousandth (0.001) of an inch. This accuracy makes them invaluable for inspecting tight tolerances.

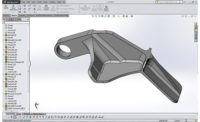

As the laser scanner’s light sweeps across an object’s surface, the device analyzes the reflected light and calculates the distance from the scanner to each geospatial point on the surface. This process generates a “point cloud” consisting of XYZ and IJK coordinates that represent the object’s surface shapes, contours, and dimensions. Integrated software converts the point cloud into a stereolithography (STL) polygonal file for creating 3D models in CAD formats like CATIA, Pro E/CREO, and SolidWorks. Engineers use the models of the object for measurement, analysis, reverse engineering, inspection, rapid prototyping, or mass production.

How Scanning Improves the Design, Manufacturing, Certification, and Replacement of Military Parts and Equipment

In pursuit of better military production, 3D scanning can be transformative, offering benefits in speed, precision, efficiency, cost-effectiveness, and quality. Here are some of the ways that 3D scanning can benefit the military and its contractors, and achieve the aforementioned goals:

Improve designs. Design optimization is faster and easier when scanning is involved. Having the detailed CAD file of an as-built part gives design engineers the capacity to examine its design in precise detail from every angle, try out modifications, correct flaws, quickly create prototypes, and more.

Improve Manufacturing Quality. 3D scanning provides precise first-article inspection, automatically comparing scanned physical parts with their original design data and calling out any deviations. This reduces manufacturing errors, ensuring that as-built parts conform to the OEM designs. (The ability to detect deviations early in the manufacturing process is especially helpful with difficult-to-measure parts like turbine blades.) The data can also be used to perform quality control and inspection analysis on as-built parts for a fast “go/no go” decision in manufacturing.

Tool and die industries benefit greatly from 3D scanning, as it excels at analyzing and revealing any tooling flaws that exist. Once scanning has revealed flaws in, say, a die, it can then be modified and re-machined.

Scanning services can also provide comprehensive inspection reports that include color deviation reports, cross-section analysis, specific 2D/3D dimensions, feature analysis, and geometric dimensioning and tolerancing (GD&T).

Accelerate certification. By swiftly detecting deviations from the original design with an accuracy of +- 0.001” or greater, 3D scanning also speeds certification. This rapid identification of deviations enables manufacturers to promptly rectify any discrepancies, ensuring the product aligns with specifications. Digital files can then be efficiently generated to certify that manufacturing standards meet quality requirements.

In repair certification, 3D scanning proves invaluable. Some Federal Aviation Administration (FAA) certified repair stations utilize scanning to document their work on passenger jet parts with such precision that they can obtain FAA approval for the repair in significantly reduced timeframes compared to conventional methods.

Rapidly create replacement parts. Scanning is impressive at expediting parts repair and replacement. Its ability to quickly create a CAD file of an as-built part is especially valuable in cases where the original design files are unavailable or a part is no longer produced. Scanning lets military engineers swiftly reverse-engineer damaged or aging parts to create CAD files for fast repair or replication. The parts can quickly be machined and reinstalled, restoring operational efficiency.

Several United States Air Force, Naval Air Stations, and other military facilities have already integrated 3D scanning into their repair protocol, with substantial savings in reduced time and cost. For example, the Corpus Christi Army Depot (CCAD) slashed the time needed to reverse engineer rotary wing components from two weeks to two hours, getting aircraft back into service much faster.

3D scanning is a readily accessible solution for manufacturers of any size. Professional scanning services are available for those who don’t require a full-time, in-house scanner or have concerns about the scanning process. These services yield excellent results, constituting a significant aspect of the military’s utilization of 3D measurement technology.

With its precision, 3D scanning distinguishes itself from conventional measurement tools. It has revolutionized accuracy in measurement and even broadened the scope of what can be accurately measured. As the number of defense contractors embracing its multiple capabilities continues to increase, the integration of 3D scanning into military manufacturing is poised to play a crucial role in ensuring the ongoing readiness of our nation’s defense forces.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!