In traditional manufacturing, companies often make parts, measure them, and discard those that don't meet standards. This wastes materials and energy. 3D measurement changes this process.

This technology measures parts and components precisely, allowing companies to spot and fix problems early in production. It enables manufacturers to compare each part to its digital design in real time. When quality teams find differences, they can adjust the process immediately, which reduces the number of defective parts and saves materials.

3D measurement also improves precision. With more accurate measurements, manufacturers make parts that consistently meet specifications. This means less rework, which saves energy and materials.

This approach also helps manufacturers optimize raw material use, as accurate measurements allow manufacturers to use just the right amount of material for each part. This cuts waste and reduces costs.

What’s more, precise measurements let manufacturers explore new, sustainable materials. Some eco-friendly materials require more exact production processes. 3D measurement provides the accuracy needed to work with these materials confidently.

In automated factories, 3D measurement offers accurate data that helps machines work more efficiently. This streamlines production and reduces energy use.

Many companies are already using 3D measurement to improve sustainability. For example:

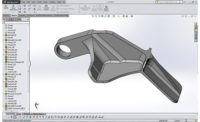

- Automotive parts makers use 3D scanners to check complex components, catching errors early to reduce scrap.

- Electronics manufacturers use in-line 3D measurement to fine-tune their circuit board production, cutting material waste and energy use.

- Packaging companies use 3D measurement to optimize their plastic designs, reducing plastic use without compromising strength.

While 3D measurement technology requires investment in equipment and training, many manufacturers find it pays off through reduced waste and improved efficiency.