Home » manufacturing

Articles Tagged with ''manufacturing''

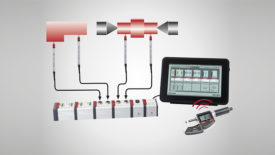

Real-time SPC, otherwise known as in-line SPC, is characterized by employing SPC during production.

Read More

Speaking of Quality | Heather Wilson

Quality Approaches to Software Management

Modern software applications are capable of numerious customizations, which present a unique set of challenges.

March 15, 2022

Face of Quality | Jim L. Smith

Transformation: History Reveals That Modernaization Creates More Jobs Than it Elminates

March 15, 2022

From the Editor | Darryl Seland

From Every Theory in Moderation?

Or firing the silver bullet?

March 15, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Test & Inspection

Aerospace Companies Flying High With 3D Laser Trackers

Portable metrology tools like 3D laser trackers are efficient solutions that can be implemented into aerospace workflows.

March 8, 2022

Measurement

It is Never Too Late to Teach an Old Custom Gage New Tricks

There are myriad ways to breathe new life into existing gages without the need to invest in new gaging.

March 8, 2022

Quality 101

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

Management

2022 Quality Plant of the Year: Larsen Manufacturing

Larsen Manufacturing is an industry leader in quality systems and quality assurance.

March 2, 2022

Vision & Sensors | Machine Vision 101

Advancements In Telecentric Technology

As telecentric lenses become more compact, the overall footprint of vision systems will follow.

March 2, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing