ZEISS Industrial Quality Solutions

ZEISS Industrial Quality Solutions. For more information, email info.metrology.us@zeiss.com or visit zeiss.com/metrology.

ARTICLES

Quality 101

Don't sacrifice quality by using the wrong styli and probe extensions.

Read More

High- Speed Measurement

Precision at All Altitudes: High-speed Measuring of Aerospace Parts with Shopfloor CMMs

Quality assurance performed at the site of production can identify and possibly even avoid manufacturing errors.

May 16, 2023

Measurement

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Case Study

A Complete View: Quality Assurance for Premium Headlights

Quality assurance at ZKW Lighting Systems had increasingly reached its limits with conventional measurement technology.

February 10, 2023

Case Study

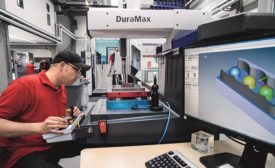

Miltera Achieves Success with ZEISS Industrial Quality Solutions

Miltera has built up a reputation as a specialist in producing everything from racecar parts to mold components, consumer electronics, turbine compressors and turbochargers for the aerospace industry.

August 16, 2022

Case Study

MRB Guss Ensures the Quality of Its Cast Parts with X-ray

With an x-ray inspection machine, the company is able to guarantee the quality of the castings faster and more comprehensively.

June 8, 2022

Quality 101

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

Improving Your Manufacturing Productivity and Quality with CMM Networking and Automation

Consider automating and moving your CMMs to the shop floor.

January 1, 2020

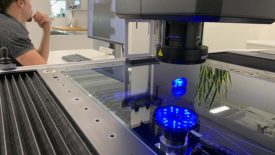

Fully Leveraging Machine Uptime

Offset measurements away from the machine tool boost manufacturing efficiency.

November 5, 2019

Achieving the Ideal Measuring Room with the Right Accessories

It’s critical to optimize your measurement machines and quality program with the right tools for your application.

September 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing