Home » manufacturing

Articles Tagged with ''manufacturing''

The Coordinate Metrology Society and PrecisionPath Consortium Launch a 3D Measurement Industry Survey

Calling Users and Managers of CMMs, Industrial Scanners, and Portable Metrology Systems to Participate in Study

May 20, 2020

Sponsored Content

White Paper: How to Solve Productivity Issues with Automated Quality Control

May 6, 2020

Smart 3D Robot Vision: The Science of Seamless System Integration

Learn how 3D smart sensors can be tightly integrated with robots to achieve a number of dynamic manufacturing processes.

May 4, 2020

Guest Editorial Comment

Quality in the Time of COVID-19

What a world we’re living in.

May 1, 2020

Error-Proof Your Inspection Reporting

How to quickly solve your missed requirements, out of tolerance and out of FAI compliance issues.

May 1, 2020

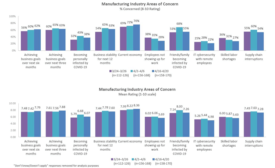

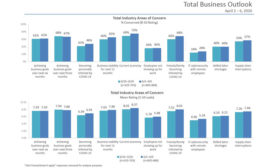

COVID-19 Prompts Economic Worries

Our third COVID-19 survey looks at how manufacturers are dealing with the pandemic.

April 27, 2020

Manufacturers Release “American Renewal Action Plan”

Timmons: The Nation Is Counting on Manufacturers

April 21, 2020

The Latest Responses to the Coronavirus

Our second COVID-19 survey looks at how manufacturers are dealing with the pandemic.

April 10, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing