ARTICLES

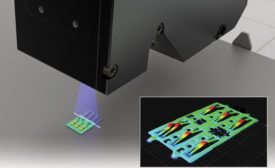

Learn how 3D smart sensors can be tightly integrated with robots to achieve a number of dynamic manufacturing processes.

Read More

Advancing Factory Automation with Smart 3D Imaging and Inspection

The Industrial Internet of Things and the Move Toward Smart Technologies

May 8, 2019

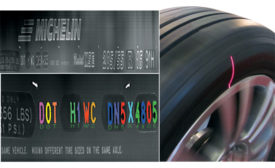

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

On the Frontier of Factory Production

Explore edge computing and smart sensors for IIoT.

March 1, 2018

Solving the Challenges of Multi-Sensor Networking

Creating a successful, robust network of sensors requires careful design.

July 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing