Home » manufacturing

Articles Tagged with ''manufacturing''

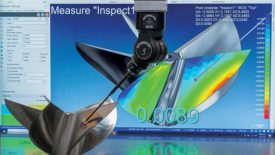

Vision & Sensors | Trends

Trends in the Machine Vision Market

Observations on the market and the technologies that could be the next to impact applications in automation.

January 4, 2023

Vision & Sensors | Machine Vision 101

Machine Vision Standards: A Review and Update

Over machine vision's long history in industrial automation, the emergence and development of standards has been one of the key drivers in advancing this technology.

January 3, 2023

The Spending Forecast is Here

The 22nd Annual Quality Spending Survey Results

Concerns about Covid-19 are down, but inflation worries are up.

December 29, 2022

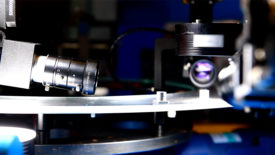

Vision & Sensors | Machine Vision 101

Machine Vision Lighting and Why It’s Important

When considering illumination, the object or field to be imaged is really what matters.

December 21, 2022

From the Editor | Darryl Seland

The Cosmos and the Rubik's Cube

Multidimensionality

December 21, 2022

Speaking of Quality | Duke Okes

The Multidimensionality of Quality

Quality offers endless opportunities to learn and contribute to the success of the organization and its employees, customers and suppliers.

December 20, 2022

Face of Quality | Jim L. Smith

Should Quality Professionals Focus on Soft Skills?

December 16, 2022

Quality 101

Nondestructive Testing Using the Resonance Acoustic Method

RAM is a volumetric approach and evaluates the whole part, both for internal and external structural flaws, metallurgical deviations, and consistency.

December 15, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing