Home » manufacturing

Articles Tagged with ''manufacturing''

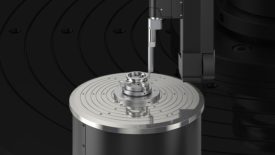

Measurement

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

Read More

Quality Headline

Next-Generation OEM Objectives Enable Engineers to Develop the Scientific Instruments of Tomorrow

July 18, 2022

Quality Headline

Nano Dimension Acquires Admatec and Formatec, Creating Metal & Ceramic Additive Manufacturing Portfolio

July 18, 2022

Quality 101

Know Your True Cost of Quality with Integrated ERP

In the end, the true cost of quality comes down to the cost of making the part plus the cost of bad parts.

July 15, 2022

Speaking of Quality | Jim Spichiger

ASQ are a Local Global Community

ASQ members dont just join an organziation, they join a thriving group of professionals who are passionate about quality.

July 15, 2022

Face of Quality | Jim L. Smith

Tips for Success, Part 1

Organizations should focus on important actions.

July 15, 2022

From the Editor | Darryl Seland

The Quality Engineer: Perception Versus Truth

July 15, 2022

How SPC Can Lead to Zero Defects

Manufacturers are already producing data. For organizations to get full value from that information, they should choose a Statistical Process Control (SPC) solution that configures notifications, automatic alarms, emails, and process alerts.

July 12, 2022

Aerospace | Back 2 Basics

Aerospace Quality Management System (AQMS) Certification

If you really want a QMS to work, you need to work at it.

July 8, 2022

Aerospace | Leak Testing

The How’s and Why’s of Leak Testing

In the aerospace field, old leak testing methods are replaced to improve efficiency and minimize time on the ground.

July 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing