Home » manufacturing

Articles Tagged with ''manufacturing''

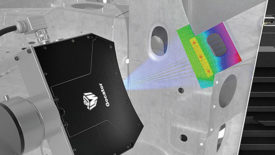

Aerospace | NDT in Aerospace

CT-Scan Data Analysis and Visualization for Aerospace NDT

For as long as there has been commercial and military flight, aircraft component suppliers have been charged with providing dimensional and process control-related data.

July 8, 2022

Test & Inspection: Measuring Magnetic Properties

Measuring magnetic properties can determine the effect of heat treatment on a material

July 8, 2022

Test & Inspection: Hardness Testing of Coatings

There are a wide variety of testing techniques for hardness, using different principles and reporting different scales.

July 8, 2022

Vision & Sensors | Machine Vision 101

The Use Of Machine Vision For Robot Guidance Offers New Possibilities

Effective robot guidance requires specific machine vision sensors and techniques.

July 6, 2022

Vision & Sensors | Vision

The Perfect Pair: Combining AI And Computer Vision

While AI can provide new capability to a vision system, it is not the only option.

July 6, 2022

Vision & Sensors | System Integration

The Power Of Embedded GPU-Driven Smart Sensor Acceleration

There are four common reasons manufacturers would need to use a smart vision accelerator to enhance the inspection performance of their sensor.

July 6, 2022

Vision & Sensors | Cameras

AI Vision Development for Everyone

The time it takes moving from a concept to a running application can be greatly reduced.

July 4, 2022

Management | The State of Satisfaction

The 2022 Quality State of the Profession

Despite suppy chain interruptions, skilled labor shortages, and inflation, quality professionals are largely satisfied with their career.

July 1, 2022

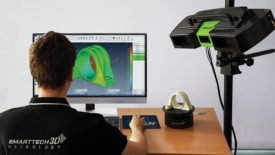

Software & Analysis

Automating Scan-Based Inspection for Repeatable Process Control

Metrology software is at the core of process control because it manages all the measurements and drives productivity.

July 1, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing