Home » color measurement

Articles Tagged with ''color measurement''

The Metrology Corner | Emil Hazarian

The time resilience is a testament to their quality where measurements played a determining role.

Read More

Quality 101

Accurate, Reliable Color Management Starts With Right Tools and Right Partner

True Colors

March 12, 2024

Measurement

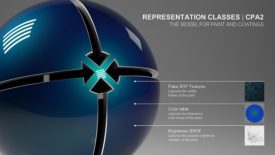

Why Digital Workflows Require More Than Digital Color

If you only digitize color using spectral data, you are missing valuable data required for the digital design and visualization workflow.

December 29, 2023

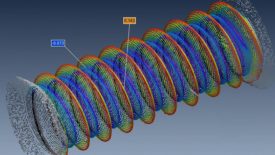

More than Laser Gages - Available Today

The added twist in recent years has been the use of a chromatic or "color" focus effect where different colors of light focus at different distances.

August 2, 2023

Revolutionizing Color Quality Control through Technology and Sustainability

Advancements in digital color measurement technologies and cloud-based software have transformed color quality control, enabling greater accuracy, efficiency, and sustainability, while automation and circular economy principles are driving further innovation in the industry.

July 12, 2023

Color Measurement

Is Your Color Workflow Resilient for Today’s Supply Challenges?

Capturing and analyzing color data can help identify areas for improvement.

October 1, 2022

Vision & Sensors | Sensors

Smart Color Sensor Technology

For color detection, color measurement and innovative automation tasks.

September 1, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Getting Color Right (It's Trickier Than It Sounds)

What you need to know for effective color management.

January 6, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing