Home » scanning

Articles Tagged with ''scanning''

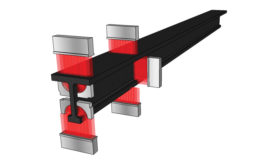

Many have found that modular tooling is a key decision making process for working with all types of measuring systems.

Read More

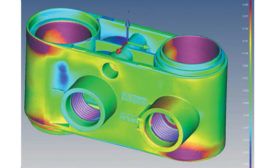

Blue Light Optical Scanning for High Resolution 3D Measurement

When an entire shape needs to be scanned, optical measurement is more effective.

September 1, 2017

The Advantages of Adaptive Ultrasonic Phased Array for Inspecting Composite Aircraft Components with Complex Geometry

Ultrasonic phased array technology is widely used to inspect composite components in aircraft.

August 1, 2017

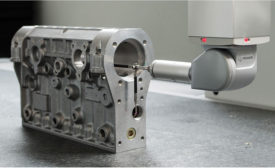

Certified Inspection with CT Scanning

The most accurate CT scanning systems are built like a CMM with an X-ray probe.

July 1, 2016

Advertisement

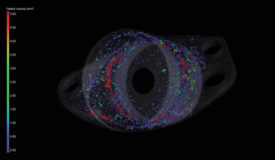

7 Metrology Methods Compared on 1 Identical Part

Your Guide to Quality and Inspection Methods and Machines

July 13, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing