Linda Marino

Linda Marino is the president of Paul W. Marino Gages Inc. For more information, call (800) 528-9785 or visit www.pmargage.com.

ARTICLES

Modular Fixturing for Clay Model Making Today

Emerging autonomous vehicle companies have joined forces with automakers worldwide in designing new vehicles utilizing modular fixturing.

March 2, 2020

Fixturing 101: The Sky is the Limit

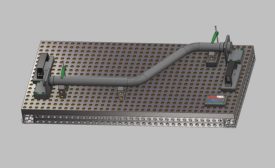

Fixturing tubular parts in aerospace duct fabrication with traditional vs. modular systems.

July 1, 2019

Modular Fixturing: How It Works

Many have found that modular tooling is a key decision making process for working with all types of measuring systems.

January 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing