Home » data collection

Articles Tagged with ''data collection''

Sponsored Content

4 Steps for Data Collection along the Industrial Internet of Things Path

July 15, 2019

Drive Improvement with Data

Achieve greater insight into the operations and make decisions based on data.

May 1, 2019

Move from “Inspect and Reject” to “Predict and Prevent” with SPC Software

A senior quality leader details his approach to making significant quality improvements.

April 2, 2019

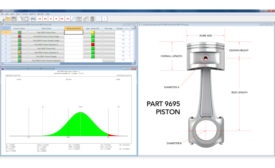

The Value of One Software for Several Types of Inspection Systems

A common software for multiple instruments, often from multiple OEMs, is ideal.

April 2, 2019

Better Quality with the Internet of Things

The connected factory meets quality.

April 2, 2019

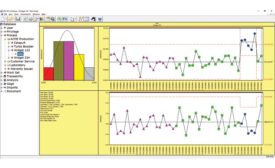

How to Statistically Control the Process

When disruptions are detected, it’s critical that operators have the tools available to quickly diagnose and correct the issues.

April 1, 2019

Choosing the Right Smart Handheld Gage

Gages bring a whole new level of measuring capability to the user.

March 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing