Home » shaft measurement

Articles Tagged with ''shaft measurement''

Considerations for Precision Shaft Measurement

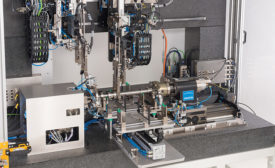

Selecting the best measuring solution for a complex shaft can be a confusing proposition.

April 1, 2016

Shaft Measurement 101

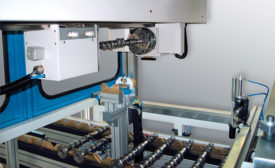

Learn more about high productivity, high precision shaft measuring.

July 2, 2015

Shaft Measurement 101

Shaft measurement tools have proven their reliability at manufacturing sites around the world.

January 7, 2014

Measurement

Advances in Shaft Measurement

As shaft measurement systems have gained popularity, users have been demanding more and more capabilities from them.

April 3, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing