Home » ct

Articles Tagged with ''ct''

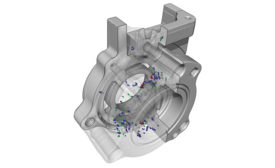

The Future of 3D Printing

With the combination of CT technology and 3D printing, many new applications are possible.

March 1, 2017

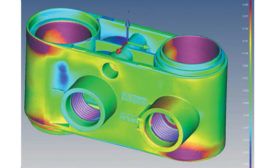

Certified Inspection with CT Scanning

The most accurate CT scanning systems are built like a CMM with an X-ray probe.

July 1, 2016

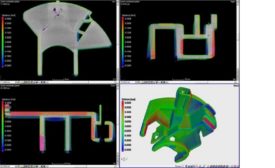

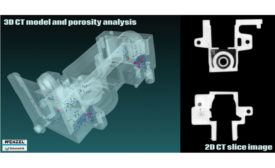

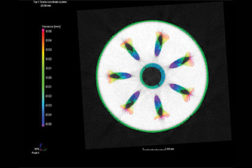

Trends in CT Scanners

Metrology companies take a longer look at computed tomography

November 6, 2015

NDT

Calibrating X-ray CT Systems

Learn more about the two main methods of calibrating CT data

April 2, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing