Home » analysis

Articles Tagged with ''analysis''

Here’s how to get there.

Read More

Missing the Point: Gage Variability and Operational Definitions

Clear operational definitions can prevent chaos.

April 16, 2018

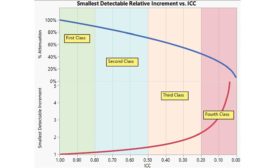

The Cost of a Poor Measurement System

Convince people of the value of measurement system analysis.

July 1, 2017

Playing to Our Strengths

Often ignored in favor of improving weaknesses.

September 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing