Home » eddy current

Articles Tagged with ''eddy current''

NDT | Back 2 Basics

This versatile tool can be used to solve or prevent material with property issues from leaving a munufacturing facility.

Read More

Eddy Current

The Big Deal about ECA

With the latest instruments and probes, eddy current array strikes a balance in speed, POD, and cost effectiveness on big jobs.

April 8, 2021

Choosing and Applying NDT Methods for Round Stock during Production

There are many approaches to NDT inspection, ranging from full system tests to in-process inspection of partially finished products.

November 8, 2019

NDT in Aerospace

Automated Eddy Current Testing Solution for Aero-engine Discs

Eddy current testing is a crucial part of quality control.

July 8, 2019

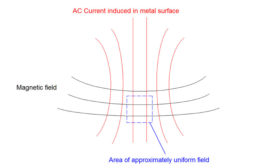

Alternating Current Field Measurement Testing

A number of industries use ACFM to inspect welded connections for surface-breaking defects.

November 1, 2018

NDT HEADLINE

Zetec Celebrates 50 Years of Providing NDT Inspection Technology Solutions

September 7, 2018

NDT WEB EXCLUSIVE

Eddy Current NDT Equipment Market to Reach $538 Million by 2026

June 8, 2018

The Precision of a New Generation

Eddy current sensors have continuously improved and adapted to new requirements.

June 8, 2018

Digital Transformation and IoT comes to Eddy Current Testing

Managers can now capitalize on the data and be more responsive to production issues as they arise.

April 2, 2018

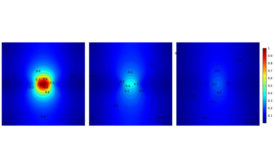

Overcoming the Adverse Effects of Galvanized Steel Weather Jackets

There are several ways of mitigating the effects of galvanized steel on pulsed eddy current inspections.

Marco Michele Sisto

Vincent Demers-Carpentier

Maxime Rochette

Marie-Eve Myrand-Lapierre

Andreanne Potvin

Florian Hardy

October 17, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing