Home » imaging

Articles Tagged with ''imaging''

Vision & Sensors | Optics

Choosing the right optical setup is critical to minimizing errors and ensuring that dimensional measurements are repeatable and reliable.

Read More

Vision & Sensors | Cameras

How RGB-IR Cameras Are Transforming Medical Imaging

Modern medical imaging systems can leverage the strengths of both spectra, leading to improved diagnostic capabilities and superior imaging across various medical use cases.

April 1, 2025

NDT | Aerospace

Neutron Imaging Advances Aerospace Valve Inspection Capabilities

The complexity of modern aerospace valves creates a particular challenge for traditional inspection methods.

January 2, 2025

Vision & Sensors | Trends

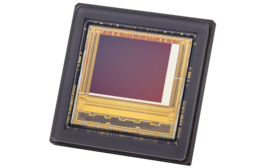

Innovations Shaping the Future of Contact Image Sensor Technology

High speed, resolution, and dynamic range imaging with true metrology in a compact design

November 26, 2024

Vision & Sensors | Trends

Eliminate Distortion in Wide Angle Imaging for Machine Vision Applications

Modern vision systems need high performance, wide angle lenses that can display high resolution images of large areas in real time.

November 25, 2024

New Product

MidOpt SiLWIR Silicon Protective Windows for Industrial Imaging

October 6, 2024

Vision & Sensors | Trends

Machine Vision Technologies Adapt for Higher Speeds, Evolving Needs

From the warehouse to the food production line, today’s high-speed imaging applications require more than just faster cameras.

June 3, 2024

Vision & Sensors | Lenses

Understanding the Key Factors in Microscope Objective Performance

February 6, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing