Home » vision systems

Articles Tagged with ''vision systems''

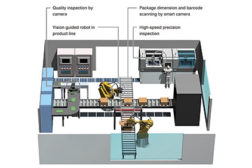

The Dawn of the Smart Factory

INDUSTRIAL SMART CAMERAS ADVANCE AS EMBEDDED VISION SYSTEMS WITH NEW GENERATION PROCESSORS ARE INTRODUCED.

September 11, 2014

Turnkey Machine Vision Systems

Today’s tools can make even the most difficult vision inspections plausible

December 10, 2013

Vision & Sensors - Image Analysis

Encoder Input Improves Part Inspection

Adding an encoder to provide a distance-based input trigger can eliminate automated inspection errors.

May 8, 2013

Vision & Sensors - Color Analysis

Choose the Appropriate Vision System

Modern manufacturing calls for accurate inspection methods.

January 2, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing