Home » ASME standard

Articles Tagged with ''ASME standard''

Measurement

Better Measurement Data Reporting to Improve GD&T Effectiveness

ASME Y14.45-2021 Standardizes Measurement Data Content for GD&T Specifications.

April 4, 2024

Quality 101

Taper Pipe Thread Inspection, NPT

If you take care of your gages, they will take care of you and the parts you manufacture.

March 2, 2023

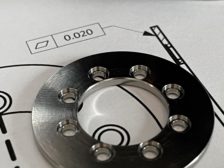

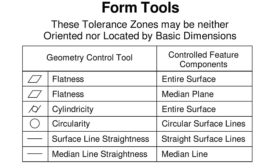

GD&T’s New Rule and What it means for Measurement

Here we will explore the implications of rule "S" and the limits/requirements of today's metrology as it is applied to these GD&T requirements.

May 6, 2021

Other Dimensions | Hill Cox

Thread Plug Gage Calibration

What's required to measure the most common elements of a thread plug gage.

March 5, 2021

Gages for Screw Thread Inserts (STI)

It is critical for both the gage manufacturer and the metrology lab to know the industry standard for the gages being manufactured or calibrated.

November 2, 2020

Standards: Who Writes that Stuff Anyway?

Once a new standard is written that is not the end of it all.

January 15, 2019

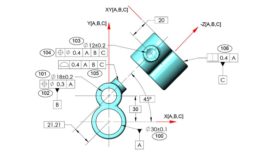

Empowering GD&T

Based on the ASME Y14.5 2009 Standard. Without GD&T, manufacturing is a guessing game.

June 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing