Home » metrology

Articles Tagged with ''metrology''

Quality in Automation | Case Study

Perhaps you already know you want to procure a vision system but are wondering how to go about specifying the system.

Read More

Quality in Automation | Artificial Intelligence

The Future of AI for Visual Inspection and Visual Quality Control in Electronics

With the rise of AI and the global restructuring of where goods are manufactured, leaders must devise a new strategy for visual quality control.

March 29, 2024

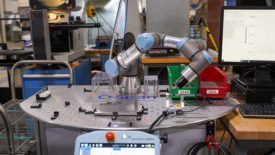

Quality in Automation | Automation

Leveraging automation for quality gains

As automation simplifies and enhances manufacturing processes, quality control staff see significant career advantages, making a shift towards more efficient, consistent, and data-driven production environments.

March 29, 2024

Speaking of Quality | Jim Spichiger

Not Either/Or but Both

You never know who you will meet.

March 29, 2024

Column | John Vandenbemden

Is Customer Satisfaction Dead?

Human nature requires face-to-face interaction as a key component for happiness.

March 28, 2024

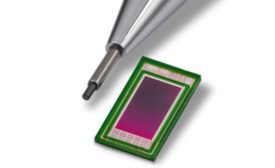

New Product

IDS Industrial Camera Offer Sony Sensor IMX662 in Both Color and Mono

March 26, 2024

Quality Headline

Boeing Identifies Process Control Issue; Key Execs to Step Down

March 25, 2024

Measurement

Consider the Indicating Plug Gage

It uses the plug body, not the contacts, to center the age.

March 25, 2024

Test & Inspection

How to Improve Quality Control by Managing a Drifting Zero Point during Air Leak Testing

Why zero drift occurs and ways to mitigate or even eliminate it.

March 25, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1711968358&width=275)