Home » Geometric Dimensioning and Tolerancing (GD&T)

Articles Tagged with ''Geometric Dimensioning and Tolerancing (GD&T)''

From the Editor | Darryl Seland

Measurement

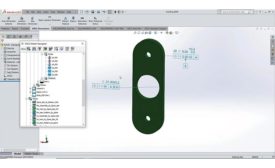

Turning GD&T From Grim, Depressing & Troublesome Into Something Grand, Delightful & Tantalizing

For the sake of industries around the world, it is time to make GD&T much easier to use, and much easier to use correctly.

February 1, 2022

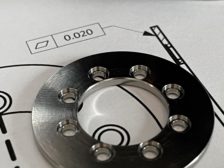

GD&T’s New Rule and What it means for Measurement

Here we will explore the implications of rule "S" and the limits/requirements of today's metrology as it is applied to these GD&T requirements.

May 6, 2021

Not All that is Green is Good

There are methods to hide bad product under green numbers.

December 1, 2020

Inspection Software Evolving to All-In-One QMS Solutions for Practical Data Management

Data-driven manufacturing is here.

September 29, 2020

Manufacturing Medical

Medical devices warrant high levels of traceability in order to obtain, track and analyze data.

March 2, 2020

Sponsored Content

Industrial Evolution: Bringing QA to the Point of Production

January 29, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing