Home » repeatable processes

Articles Tagged with ''repeatable processes''

Understanding Accuracy for Computed Tomography

If you take time to understand these definitions, standards and testing methods, you’ll be able to determine the accuracy of CT in your specific application.

October 5, 2020

The Veteran of Noncontact Metrology

Is air gaging still relevant in the 21st century?

September 2, 2020

New Lessons in Gage Management: Don’t Overlook GR&R Testing

Strong gage management and tracking impacts a manufacturer's ability to grow, experts say.

August 31, 2020

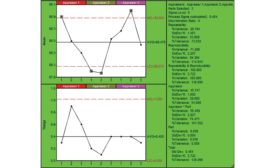

An R&R Study

In most situations, you're likely to be surprised by the amount of R&R error detected.

June 30, 2020

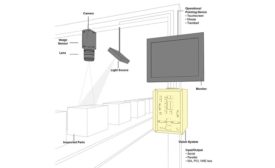

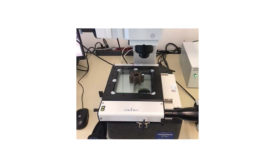

A Quality Assurance Toolset for Modern Manufacturers

Before you can fully utilize machine vision, you need to understand the basics.

January 8, 2020

Choosing and Applying NDT Methods for Round Stock during Production

There are many approaches to NDT inspection, ranging from full system tests to in-process inspection of partially finished products.

November 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing