Home » high resolution

Articles Tagged with ''high resolution''

Vision & Sensors | Lighting

Computational imaging can simplify certain problems that are difficult to solve with standard visual imaging.

Read More

The Importance of Lighting Control

Appropriate lighting can be critical to the success or failure of the project.

September 1, 2020

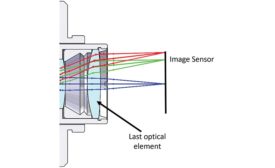

Design Considerations for New High Resolution and Frame Rate CMOS Sensors

Sensors will continue to evolve, and camera lenses will continue evolving right along with them.

January 1, 2020

Shaft Measurement: What is the Best Tool for the Job?

Shaft measurement can be performed with a variety of metrology tools, from handheld devices to high-end coordinate measuring machines.

November 1, 2019

Machine Vision Lens Performance

A number of factors are important in lens design, including lens resolution, spatial distortion, and uniformity of illumination.

May 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing