Home » CoaXPress

Articles Tagged with ''CoaXPress''

Vision & Sensors | Standards

With so many interfaces available, why is Camera Link still viable?

Read More

Vision & Sensors | Standards

CoaXPress 2.1 Over Fiber Optic Cables is Faster and More Stable

CXPoF opens a new realm of opportunities.

July 20, 2023

Vision & Sensors | Interfaces

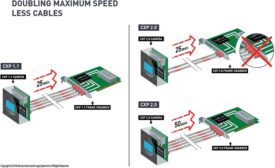

CoaXPress 2.0 – The Standard in Industrial Image Processing for Demanding Applications

The Newly Developed CoaXPress 2.0 Standard will Increase the Performance of Your Vision System With Twice the Data Rate.

July 6, 2021

Developments in Machine Vision Camera Interfaces

A number of data transfer hardware interfaces have been developed specifically for the machine vision sector over the years, including cameralink, GigE vision, USB3 vision, CoaXpress and Cameralink HS.

November 30, 2020

Interfaces for Machine Vision

Both consumer and dedicated interfaces are used across many machine vision applications.

May 5, 2020

Applying the CoaXPress Interface in Multi-Camera Machine Vision Systems

Multiple camera systems have been a fixture in machine vision for decades. What is new is the use of CXP.

January 1, 2020

Avoid Costly Missteps When Selecting a Machine Vision Interface—Now and in the Future

Selecting a machine vision interface represents a long-term investment and is always application-specific.

January 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing