Home » thread gaging

Articles Tagged with ''thread gaging''

Test & Inspection

Gaging systems can fundamentally be categorized into three groups.

Read More

Quality 101

Pre-Plate Threads: 60° Thread Form

Nobody wants to make or sell a custom gage you can’t use and are unable to return.

May 3, 2024

Test & Inspection

How Do Tap Limits Affect Gage Selection?

It is not always as simple as it sounds.

November 2, 2023

Quality 101

Taper Pipe Thread Inspection, NPT

If you take care of your gages, they will take care of you and the parts you manufacture.

March 2, 2023

Other Dimensions | Hill Cox

Thread Ring Gage Calibration

The basic advantage of the solid thread ring is that it does not have a size adjustment that can be changed.

April 8, 2021

Gages for Screw Thread Inserts (STI)

It is critical for both the gage manufacturer and the metrology lab to know the industry standard for the gages being manufactured or calibrated.

November 2, 2020

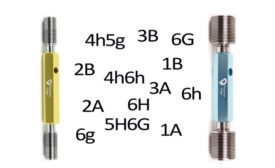

Thread Classes and Setting Plug Gages

Product tolerances and dimensions always dictate the gage tolerances and dimensions.

October 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing