Home » vision guided robotics

Articles Tagged with ''vision guided robotics''

Vision

AI-enabled software has evolved beyond hype, becoming an extremely valuable tool in the machine vision toolbox.

Read More

Vision & Sensors | Automation

Augmenting Your Workforce: Three Opportunities to Leverage Technology to Automate Repetitive Tasks

As with any good engineering approach to problem-solving, we can divide the manufacturing labor challenge into parts.

June 17, 2024

Quality in Automation | Automation

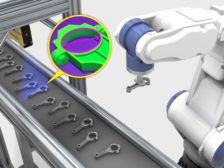

Machine Vision Advancements Simplify, Improve Vision-Guided Robot Systems

3D Imaging, AI-Based Software, and Industrial Computing Democratize Application-Specific Automation Systems.

March 29, 2024

Vision & Sensors | Vision

40+ Years of Vision Guided Robotics

VGR is one of the largest growing sectors in both the robotics and machine vision market.

May 3, 2023

Vision & Sensors | Trends

Machine Vision Developments Drive Automation Upward

As business needs grow and transform over time, suppliers continue pushing machine vision technology forward.

December 9, 2022

Vision & Sensors | Vision Robotics

How AI and Machine Vision Impact Vision Robotics

Just as humans need good data to make better decisions, so do AI systems.

September 1, 2021

2.5D Vision Hits Sweet Spot for Collaborative Applications

Automation can be deployed without having to redesign large parts of your facility.

April 8, 2021

VISION GUIDED ROBOTICS

Best Practices for Implementing Vision Guided Robotics

An important first step in any application is a thorough project evaluation prior to system design and implementation.

April 8, 2021

Machine Vision Trends

A look at the most talked-about machine vision technologies, their practical uses and limitations, and which will have a long-lasting impact on your current and fixture applications.

September 1, 2019

Simple Steps to VGR Implementation

Vision technology is constantly being updated, especially where speed and resolution are concerned.

January 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing