Home » software trends

Articles Tagged with ''software trends''

Software & Analysis

Quality professionals need to be concerned with software outside the realm of enterprise quality management systems (EQMS).

Read More

Software & Analysis

The Evolution of Quality Management Systems Software

From the CEO to the Manufacturing Floor, Access to Data Empowers the Organization to Improve.

July 8, 2021

Technology Adoption

The importance of not only how many, but also how quick.

September 1, 2020

Cost of Quality

How a cost of quality approach, already customized for software and information technology, can be applied toward the deployment and implementation of Quality 4.0 in an organization.

September 1, 2020

Adopting a Data-Centered Approach to Compliance via Software Platforms

The future of quality lies in data intelligence, and reliable software platforms can help companies be ready.

March 10, 2020

Defining the Future of ERP in a Quality-Driven World

Manufacturers require ERP systems that can “learn” what excellent quality looks like.

September 1, 2019

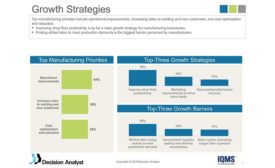

From Paper and Pencil to Industry 4.0: Revealing the Value of Data through Quality Intelligence

For manufacturers to realize the full power of quality and the data behind it, they must embrace the technology available.

October 10, 2017

The Benefits of Automating Your Document Control Process

The document control system sets the foundation for an effective quality system.

September 2, 2015

The Journey to Relevance

Six questions for turning the piles of data you’re already collecting into actionable intelligence. The data wave is building.

September 1, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing