Home » medical device manufacturing

Articles Tagged with ''medical device manufacturing''

Sponsored Content

Monte Carlo simulations specialize in computing reliable probabilities from simulated data.

Read More

Sponsored Content

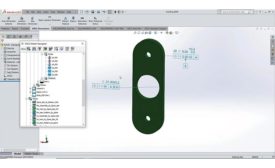

White Paper | Geometric Dimensioning of a Femoral Implant

October 28, 2021

2021 Quality Plant of the Year: Electromed, Inc.

This medical device company and essential business faced extraordinary pressure to keep up with demand while managing its own safety in a pandemic.

March 5, 2021

The Opportunities of Risk in the Supply Chain

Recognizing risks with your vendors can lead to opportunity in the wake of COVID-19.

January 19, 2021

Materials Testing Systems in Regulated Environments: What You Need to Know

In the current environment, non-compliance is not an option.

March 8, 2020

Manufacturing Medical

Medical devices warrant high levels of traceability in order to obtain, track and analyze data.

March 2, 2020

A Pulse on Quality 4.0 for Medical Device Manufacturing

In the medical device manufacturing market, there are numerous challenges to design and produce safer devices.

December 10, 2019

NDT

4 Reasons Why CT is the Best Method for Medical Device Quality Inspection

CT is a huge benefit to the medical device industry and will only continue to grow.

October 1, 2019

Four Dangerous Myths about Quality that May Cost Lives

Important lessons from a medical devices quality veteran.

April 8, 2019

Back to Basics: Testing Medical Equipment and Materials

Defects in medical devices and materials have life-or-death consequences.

December 3, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing