Home » 3D printing

Articles Tagged with ''3D printing''

INDUSTRY HEADLINE

HMS Industries Inc. Selects Rize One 3D Printer to Build Functional Tooling for Production

March 15, 2018

Staying Error-Proof with Ballbar Testing

Smart, wireless ballbars keep a wide range of businesses competitive.

March 13, 2018

INDUSTRY HEADLINE

Additive Industries to Move Headquarters to New, Larger Factory

March 6, 2018

INDUSTRY HEADLINE

Additive Industries Prepares for Growth with New Director of Operations & Supply Chain

January 10, 2018

INDUSTRY HEADLINE

Aurora Signs Agreement with DNV GL to Certify Its 3D-Printed Parts

December 8, 2017

INDUSTRY HEADLINE

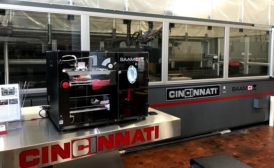

Cincinnati Incorporated Expands Additive Manufacturing Efforts with Acquisition of New Valence Robotics Corporation

December 1, 2017

INDUSTRY HEADLINE

Magnet Applications Recognized For Advancements In 3D-Printed Magnets

November 28, 2017

INDUSTRY HEADLINE

GE Additive Acquires GeonX to Strengthen Software Simulation Capabilities

November 16, 2017

INDUSTRY HEADLINE

ASTM International Seeks Partners to Launch Additive Manufacturing Center of Excellence

November 14, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing