Home » smart cameras

Articles Tagged with ''smart cameras''

Smart Cameras in a Manufacturing Environment: Today and in the Future

The combination of dramatically improving hardware and modern software technology has made smart cameras capable, inexpensive, and easy-to-use.

January 1, 2018

Automation

AUTOMATED MACHINE VISION SYSTEMS ARE FASTER, SMARTER AND MORE DETAILED THAN EVER.

March 3, 2015

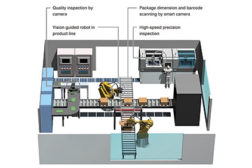

The Dawn of the Smart Factory

INDUSTRIAL SMART CAMERAS ADVANCE AS EMBEDDED VISION SYSTEMS WITH NEW GENERATION PROCESSORS ARE INTRODUCED.

September 11, 2014

Vision & Sensors - Smart Cameras

Trends in Vision: Application-specific Integrated Solution Blocks Improve Quality

January 2, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing