Home » quality inspection

Articles Tagged with ''quality inspection''

Offset measurements away from the machine tool boost manufacturing efficiency.

Read More

Sponsored Content

The Hidden Costs of Hiring in Industrial Inspection: Time for a New Alternative

October 14, 2019

Why Smart Cameras are the Ideal Solution for Traceability

Machine vision’s role in track, trace and control.

April 5, 2019

Taking Measure

The need to optimize throughput is a common denominator across industry lines.

October 3, 2017

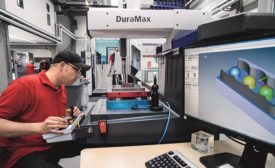

Controlling the Accuracy of a Shop Floor CMM

Understanding the influence of temperature on your CMM.

September 1, 2017

8 Reasons Controlling Color Quality is Hard

Do you ever get frustrated with the trial and error, rework and wasted materials that result when color doesn’t meet expectations?

November 1, 2016

INDUSTRY HEADLINE

TRIGO Welcomes Spanish Aerospace Quality Specialist Global Q

May 29, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing