Home » CT scanning

Articles Tagged with ''CT scanning''

Meet the quality inspection solutions for all components of E-Mobility: Battery, Power Electronics, E-Motor and Transmission.

Read More

Seeing is Believing: 2D and 3D X-ray Technologies for Nondestructive Testing

X-ray based techniques have many advantages for inspection and quality control.

November 1, 2019

NDT

Industrial CT Raises the Bar for Canyon Bicycles

Inspection with the use of industrial X-ray and computed tomography has helped Canyon Bicycles raise the bar on quality and safety.

October 1, 2019

NDT

4 Reasons Why CT is the Best Method for Medical Device Quality Inspection

CT is a huge benefit to the medical device industry and will only continue to grow.

October 1, 2019

NDT in Aerospace

Additive Manufacturing and the Inspection Processes

It is an exciting time to be in additive manufacturing.

July 8, 2019

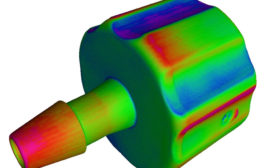

Computed Tomography Scans: The Latest Tool for Industrial Quality Evaluation

There is virtually no limit to the quality evaluation applications of CT scanning.

February 1, 2019

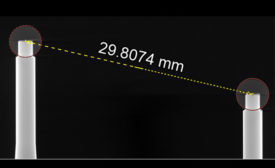

How CT Scanning Is Enhancing the Quality and Manufacturability of Medical Devices

This inspection technique is highly valuable for industrial metrology.

November 8, 2018

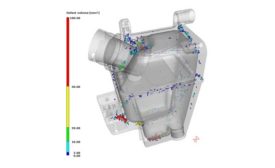

Computed Tomography: Optimizing Large Quantity Automated Measurements

Learn more about automated measurement techniques for large quantity screening applications.

October 8, 2018

Dispelling the Myths of CT

Advanced robotics, faster computers, and lean manufacturing processes are all combining to improve the efficiency of manufacturing.

October 1, 2018

INDUSTRY HEADLINE

Exact Metrology Hosts Dual Open Houses Demonstrating Newest Products And Equipment In Metrology

July 16, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing