Home » Artificial Intelligence (AI)

Articles Tagged with ''Artificial Intelligence (AI)''

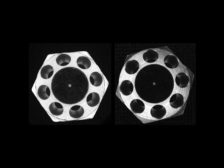

Quality in Automation | Inspection

One of the fastest ways manufacturers can add AI decision-support into processes is with image compare.

Read More

Quality in Automation | Column

Automation Use Surged in 2021 – and We’re Just Getting Started

Consider the automation trends that make it easier to automate in today's competitive environment.

April 8, 2022

Face of Quality | Jim L. Smith

Transformation: History Reveals That Modernaization Creates More Jobs Than it Elminates

March 15, 2022

Test & Inspection

How AI and Machine Vision Intersect

No matter how you slice it, machine vision has become more capable.

February 1, 2022

Vision & Sensors | Automation

Bringing AI to Visual Inspection

Adding automated decision-support for human operators helps speed visual inspection rates and improve product quality.

January 1, 2022

Quality 101

I Think I Need AI! What is AI?

For most manufacturers evaluating AI, their key concerns focus on the cost and complexity of design and deployment.

October 1, 2021

Vision & Sensors | Systems Integration

Machine Vision Systems Integration: Deep Learning

An introduction to when and how to incorporate deep learning in industrial automation applications.

September 1, 2021

Test & Inspection

How the Pandemic and Quality 4.0 are Changing Testing and Inspection

To discuss trends in testing and inspection, we must first discuss the impact of Covid-19.

August 8, 2021

Vision & Sensors | Trends

The Role of Quality in a Post-Pandemic World

It's Especially Clear That Relying on On-Site Vision Experts is no Longer a Viable Strategy.

July 6, 2021

Vision & Sensors | Machine Vision 101

Image Analysis 101: The Role of Artificial Intelligence

A Growing Number of Manufacturers are Using Deep Learning Tools, a Subset of Artificial Intelligence, to Reduce Waste and Improve production. But, Experts Say, Some of it is Just Hype.

July 6, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing