Home » compliance

Articles Tagged with ''compliance''

Digitally Transform Your Quality Compliance

Keep up to date with changing requirements while keeping the business operating profitably and in compliance.

March 15, 2020

Adopting a Data-Centered Approach to Compliance via Software Platforms

The future of quality lies in data intelligence, and reliable software platforms can help companies be ready.

March 10, 2020

Materials Testing Systems in Regulated Environments: What You Need to Know

In the current environment, non-compliance is not an option.

March 8, 2020

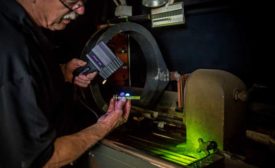

NDT Compliance: The Proper Test for High Quality Lamps

Standards are constantly getting upgraded to make NDT safe and reliable for inspectors and the public.

November 8, 2019

Balancing Compliance and Continuous Improvement in Highly Regulated Industries

Learn how several innovative manufacturers are balancing compliance and continuous improvement in their operations.

October 8, 2019

Manufacturing a Quality Medical Device

Quality is nonnegotiable in the medical field.

October 1, 2019

Quality & Corrective Actions

Ensure compliance with a robust corrective action process.

July 31, 2019

Achieving Compliance with 21 CFR Part 11: Managing Electronic Testing Data

When transitioning from paper to electronic record keeping and Part 11, companies often have several solutions to choose from.

April 1, 2019

It's Time for Risk Based Thinking

Risk based thinking can help you prevent losses, capture opportunities and improve communication throughout the organization.

February 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing